Revolutionizing Industrial Efficiency with Advanced Hydraulic Drives in Global Markets

In today's fast-paced industrial landscape, efficiency is paramount, and businesses are continually seeking innovative solutions to enhance productivity and reduce operational costs. One of the most transformative technologies making waves across global markets is advanced hydraulic drives. These state-of-the-art systems not only improve the performance of machinery but also offer unparalleled adaptability to meet the dynamic demands of various industries. By harnessing the power of hydraulic drives, companies can optimize their processes, ensuring a competitive edge in an increasingly crowded marketplace.

As industries evolve and the push for sustainability intensifies, the role of hydraulic drives becomes even more critical. They provide the capability to manage energy consumption effectively while ensuring robust operational capabilities. This blog will explore how the integration of advanced hydraulic drives into industrial processes is revolutionizing efficiency, driving innovation, and setting new standards for performance across diverse sectors worldwide. Join us as we delve into the transformative potential of hydraulic drives and their impact on the future of industrial operations.

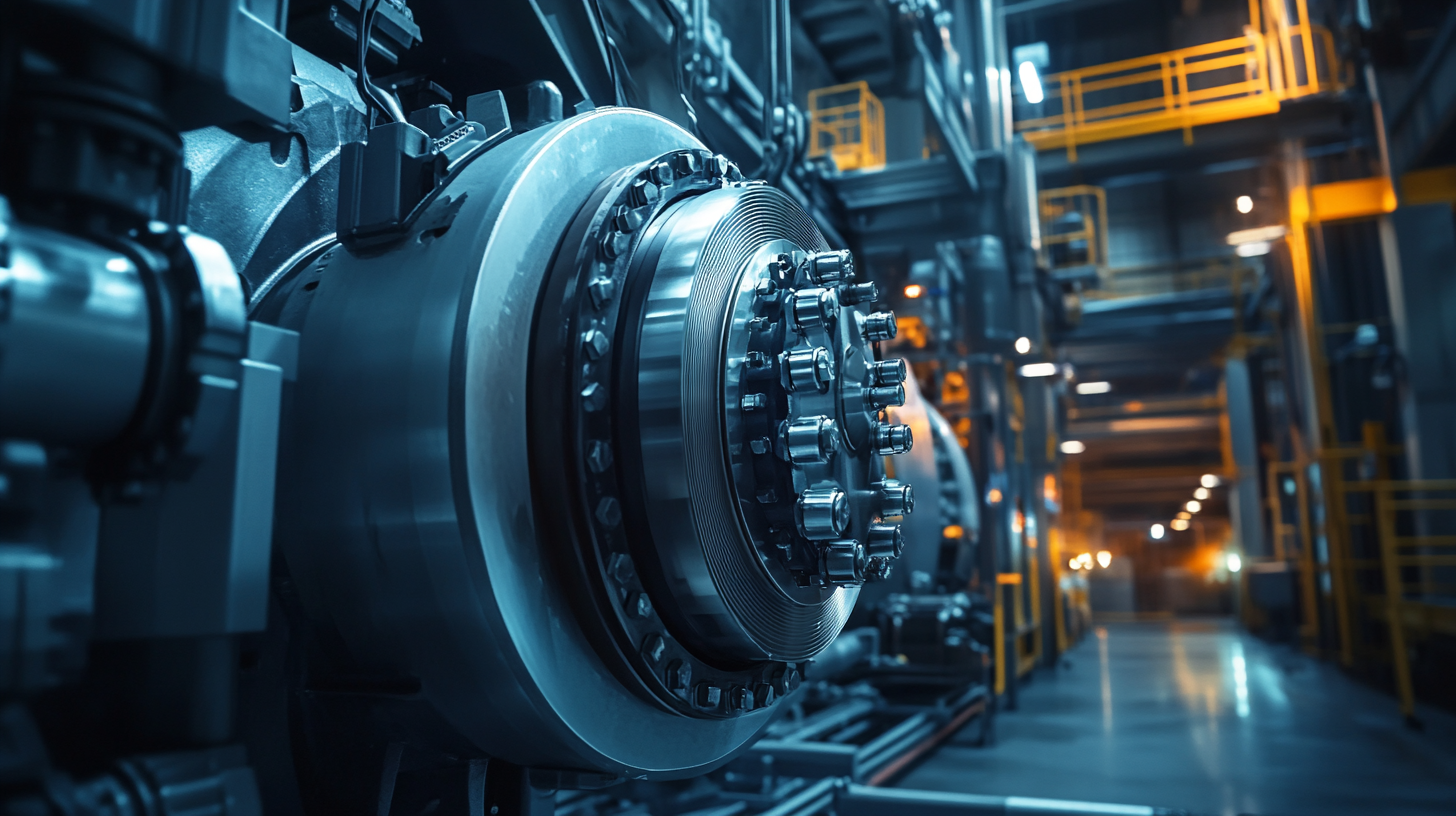

The Evolution of Hydraulic Drives in Industrial Applications

The evolution of hydraulic drives in industrial applications has transformed the way industries operate, enhancing efficiency and effectiveness across various sectors. Initially, hydraulic drives were recognized for their power and reliability, making them a preferred choice for heavy-duty tasks. Over the years, technological advances have led to the development of more sophisticated hydraulic systems, characterized by improved control mechanisms and energy efficiency. The integration of digital technologies and automation has further revolutionized hydraulic drives, allowing for real-time monitoring and adjustments that optimize performance. One of the significant advancements in hydraulic drive technology is the shift towards energy-efficient designs. With growing environmental concerns and the need for sustainable operations, manufacturers are investing in hydraulic systems that utilize less energy while delivering greater output. Innovations such as variable displacement pumps and servo-controlled actuators are at the forefront of this evolution, enabling industries to minimize their carbon footprint without sacrificing productivity. These advancements not only contribute to reducing operational costs but also align with global sustainability goals. Moreover, the flexibility of modern hydraulic systems allows them to be adapted for a wider range of applications, from manufacturing to agriculture and beyond. The ability to customize hydraulic solutions to meet specific industrial needs has made them indispensable in sectors seeking to maximize output. As industries become more competitive in the global market, the role of advanced hydraulic drives continues to expand, establishing themselves as crucial components in the pursuit of operational excellence.

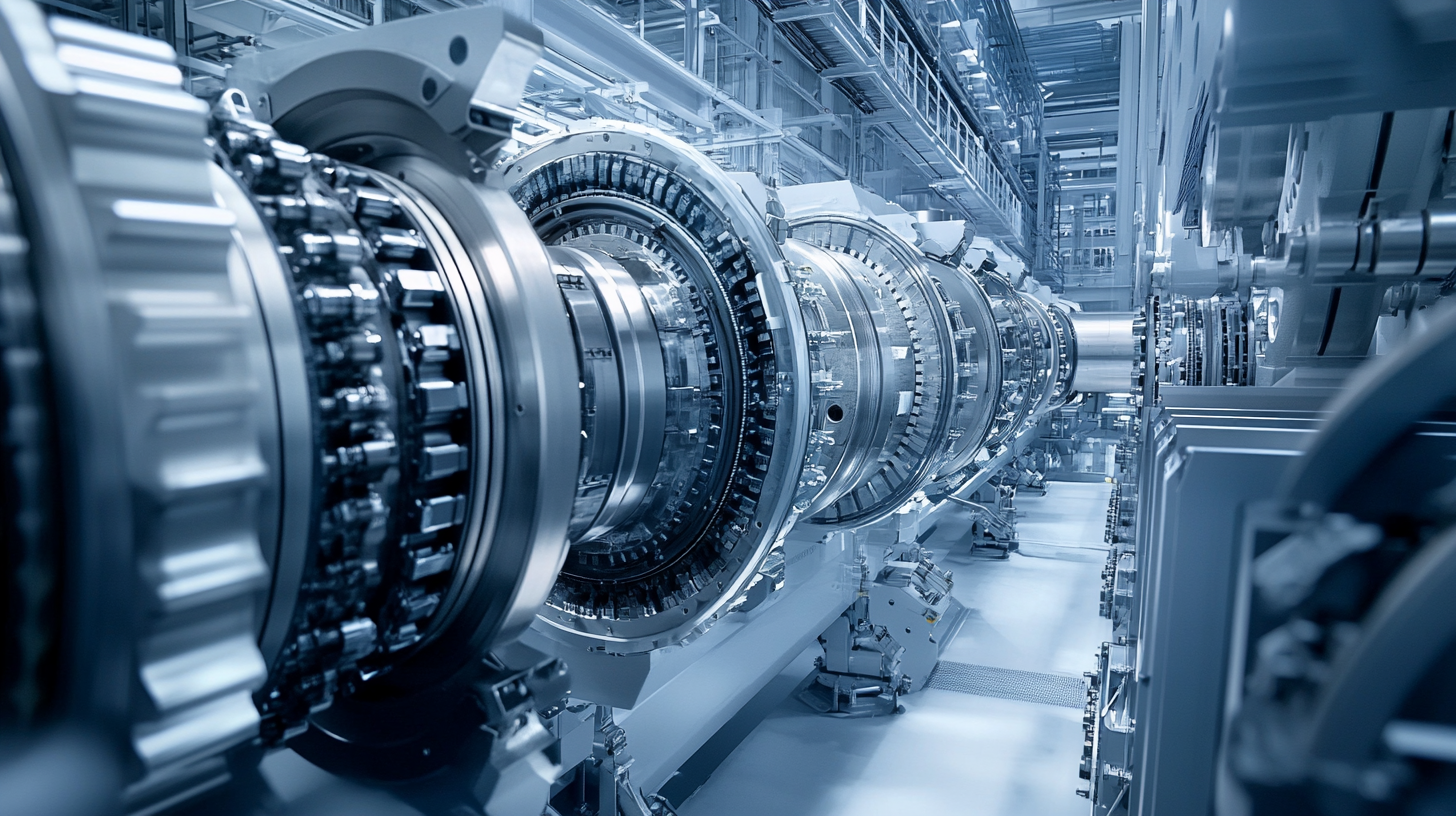

Key Benefits of Integrating Advanced Hydraulic Systems in Manufacturing

Integrating advanced hydraulic systems into manufacturing processes has become a game-changer in enhancing industrial efficiency. Recent reports indicate that the hydraulic equipment market is projected to reach $64 billion by 2026, with intelligent hydraulic power units leading the charge. These systems are equipped with smart technology that allows for real-time monitoring and autonomous adjustments, resulting in energy savings of up to 30%. By utilizing advanced hydraulic drives, manufacturers can optimize machinery performance and reduce operational costs.

One of the key benefits of these advanced systems is their ability to improve productivity. For instance, intelligent hydraulic solutions can minimize downtime through predictive maintenance, addressing potential failures before they disrupt operations. According to a study by the International Journal of Advanced Manufacturing Technology, companies that implemented such systems saw productivity increases of up to 25%. This not only accelerates production cycles but also enhances the overall reliability of manufacturing processes.

Furthermore, advanced hydraulic drives are designed with sustainability in mind. Reports indicate that these systems can reduce carbon emissions significantly. For example, the transition to intelligent hydraulic power units can lead to a decrease in energy consumption of more than 20%, aligning with global efforts to promote greener manufacturing practices. As businesses worldwide strive to comply with environmental regulations, integrating these advanced hydraulic systems proves to be a strategic move toward achieving both efficiency and sustainability.

Challenges and Solutions in Adopting Hydraulic Technology Globally

The global adoption of hydraulic technology in industrial applications presents both significant challenges and viable solutions. One of the foremost challenges is the high initial investment required for advanced hydraulic systems. According to a report by the International Fluid Power Society (IFPS), the average cost of implementing a hydraulic system can exceed $500,000, depending on the scale and complexity of the machinery. This upfront financial hurdle can deter many manufacturers, particularly small to medium-sized enterprises, from upgrading to more efficient hydraulic drives.

Furthermore, technical expertise in hydraulic system maintenance and operation remains a critical barrier. The same report highlights that more than 40% of industries report a shortage of skilled workers with specialized knowledge in hydraulic systems. This gap not only slows down the implementation of new technology but also compromises the efficiency gains that such systems promise. To address this, industry leaders are increasingly investing in training programs and partnerships with educational institutions to cultivate the next generation of hydraulic engineers.

Another challenge lies in the variability of hydraulic performance across different geographical regions, influenced by local regulations and environmental standards. The Hydraulic Institute notes that the adoption rate of hydraulic technology varies significantly, with Europe and North America leading at approximately 20% growth, while regions like Southeast Asia lag behind at just 10%. However, companies are finding solutions through tailored strategies that consider local market conditions and compliance requirements, paving the way for a more uniform global adoption of hydraulic technology. By addressing these challenges head-on, industries can unlock unprecedented levels of efficiency and productivity through advanced hydraulic drives.

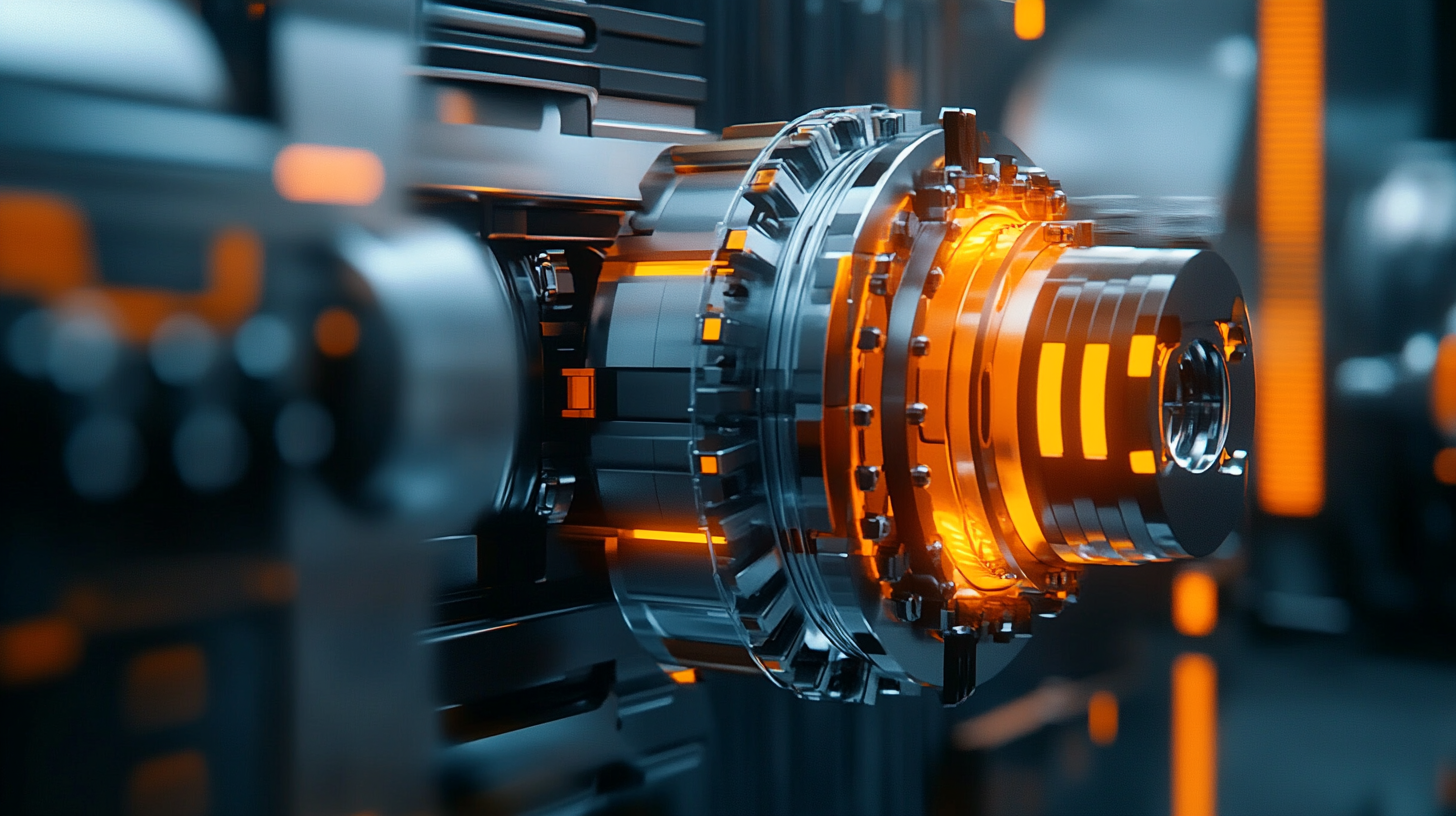

Future Trends in Hydraulic Drives: Innovations and Market Growth

The landscape of hydraulic drives is experiencing rapid transformation, driven by continuous innovations and a burgeoning global market. Advanced hydraulic systems are increasingly recognized for their ability to enhance efficiency in various industrial applications. As manufacturers seek to optimize performance, the integration of smart technologies, such as IoT and AI, into hydraulic systems has become a focal trend. These innovations enable real-time monitoring and predictive maintenance, which not only reduces downtime but also maximizes operational efficiency.

Another noteworthy trend is the shift towards energy-efficient hydraulic drives. As sustainability becomes a priority across industries, companies are investing in technologies that minimize energy consumption and carbon footprints. Electrification of hydraulic systems and the use of alternative energy sources are pivotal in this transition. Enhanced designs and materials further contribute to lightweight and compact systems, which provide greater adaptability in various environments.

The growth of emerging markets is also influencing the development of hydraulic drives. As economies expand, there is a rising demand for robust and efficient machinery, leading to increased investments in hydraulic technologies. Customization and scalability are becoming crucial, allowing manufacturers to tailor solutions that meet the specific needs of diverse industries. This evolving landscape not only promises growth for hydraulic drive manufacturers but also sets the stage for innovative collaborations and advancements that will shape the future of industrial efficiency.

Case Studies: Successful Implementation of Hydraulic Solutions Across Industries

In recent years, the application of advanced hydraulic drives has transformed various industries, showcasing remarkable efficiency improvements. For instance, the Takue Engineering Company successfully implemented innovative hydraulic solutions in their manufacturing processes, resulting in a significant reduction in energy consumption and increased productivity. By integrating state-of-the-art hydraulic technology into their machinery, they were able to enhance operational capabilities while minimizing environmental impact.

Another compelling case study can be seen in the construction sector, where hydraulic drives have revolutionized equipment functionality. Companies have adopted these advanced systems to enhance the performance of cranes and excavators, allowing for smoother and more powerful operations. Real-time data integration further optimizes hydraulics, leading to smarter decision-making and reduced downtime. The result is not only improved project timelines but also substantial cost savings across operations.

Furthermore, the agricultural sector is witnessing a similar trend, with hydraulic drives playing a crucial role in modern farming equipment. Manufacturers that have embraced hydraulic innovations report greater efficiency in tasks such as plowing, seeding, and harvesting. The ability to harness hydraulic power effectively translates into higher yield rates and reduced labor requirements, showcasing how this technology is reshaping the future of agriculture globally.