China's Smart Manufacturing Leading Global Sales of Quality Hydraulic Parts

In recent years, China's smart manufacturing revolution has positioned the country as a global leader in the production and sales of quality hydraulic parts. According to a report by Research and Markets, the global hydraulic parts market is projected to reach $66.5 billion by 2025, with a significant portion contributed by China's advanced manufacturing capabilities. This surge in demand is driven by the expansion of industries such as construction, automotive, and agriculture that rely heavily on hydraulic systems for efficient operation.

China's investment in smart technology, automation, and integration of AI in production processes is not only improving the quality of hydraulic components but also enhancing operational efficiencies. As such, businesses looking to thrive in this competitive landscape must prioritize a comprehensive checklist for sourcing high-quality hydraulic parts that meet international standards and regulations, fostering reliability and performance in their operations.

The Growing Demand for Hydraulic Parts in Smart Manufacturing Across Industries

The demand for high-quality hydraulic parts is surging across various industries, driven by the rapid advancement of smart manufacturing technologies. As companies aim to enhance efficiency and precision, hydraulic systems play a crucial role in automating processes, optimizing performance, and reducing downtime. The integration of intelligent sensors and real-time monitoring not only improves operational capabilities but also ensures high safety standards critical to modern manufacturing environments.

Tip: Consider investing in hydraulic components that leverage advanced technology, such as IoT-enabled sensors. These can provide real-time data analysis, allowing for proactive maintenance and minimizing operational disruptions.

As industries increasingly pivot towards smart manufacturing, they prioritize sourcing reliable hydraulic parts. This trend is underpinned by the need for sustainability and cost-effectiveness. Hydraulic systems that are durable and energy-efficient can help businesses meet their production goals without compromising environmental standards.

Tip: When selecting hydraulic parts, focus on vendors known for quality assurance and innovation. A supplier that offers customized solutions can better serve the unique demands of your manufacturing processes, ensuring optimal performance and longevity.

Key Applications of Hydraulic Components in Robotics and Automation

China is emerging as a leader in the global market for high-quality hydraulic parts, with significant implications for robotics and automation. Soft robotics technology is increasingly reliant on hydraulic components, enabling robots to perform delicate tasks in challenging environments, such as disaster sites. The integration of hydraulic systems into soft actuators allows for an impressive range of movement and adaptability, catering to various applications across industries. The ongoing advancements in these technologies highlight the role of hydraulics in enhancing robotic capabilities.

The hydraulics market is projected to reach approximately $44.26 billion by 2030, reflecting a robust growth trend driven by the demand for advanced automation and robotics solutions. For instance, vision-guided robots utilize hydraulic components to automate processes, moving parts weighing between 5 and 20 kilograms with precision and efficiency. This trend underscores the critical importance of high-quality hydraulic components, not only in traditional industrial settings but also in emerging applications such as soft robotics, where flexibility and sensitivity are paramount. As the industry continues to evolve, China's innovative approaches to smart manufacturing will likely position it at the forefront of this technological transformation.

Case Studies: Successful Implementation of Hydraulic Systems in Manufacturing

China's smart manufacturing sector is not only transforming domestic production capabilities but also setting benchmarks in global sales of high-quality hydraulic parts. Recent industry reports indicate that the hydraulic machinery market in China is projected to grow at a CAGR of 6.2%, reaching $15 billion by 2025. This growth is driven by the escalating demand for advanced hydraulic systems in various manufacturing applications, including automotive, aerospace, and construction.

A standout example of successful hydraulic system implementation can be seen in the recent recognition of several manufacturing reliability enhancement cases by the Ministry of Industry and Information Technology. Notably, five companies from Hunan province made it to the national list, with two cases from a leading company highlighting their innovative use of hydraulic technology. These implementations not only exemplify efficiency but also showcase how refitting traditional manufacturing setups with smart hydraulic systems can yield significant reliability improvements. The effective integration of these systems helps lower operational risks and enhances productivity, pivotal in maintaining competitive advantages both locally and globally.

How to Optimize Hydraulic Systems for Enhanced Performance and Efficiency

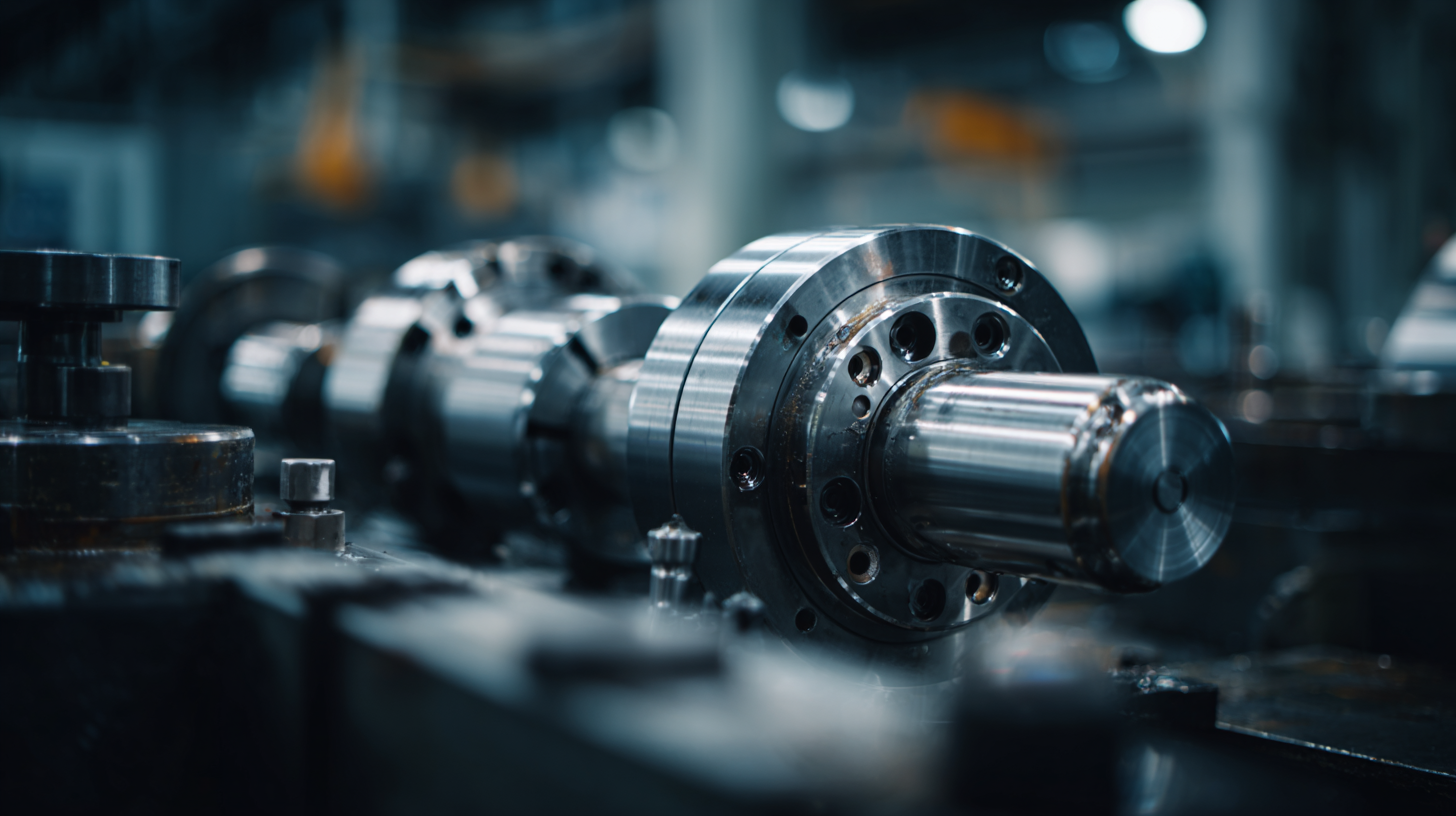

In the realm of smart manufacturing, optimizing hydraulic systems is crucial for enhancing performance and efficiency. Hydraulic systems are vital components in many industries, where precision and power are essential. To achieve maximum efficiency, regular maintenance is key. Implementing a routine check-up schedule can help identify wear and tear early, reducing the risk of unexpected downtimes.

One effective tip for improving hydraulic system performance is to select high-quality hydraulic parts that meet stringent quality standards. Investing in superior components not only ensures reliability but also contributes to overall system efficiency. Furthermore, integrating smart sensors can provide real-time data on system performance, allowing for quick adjustments and predictive maintenance, which ultimately minimizes operational costs.

Another important aspect is to focus on fluid quality. Contaminants in hydraulic fluids can lead to significant efficiency losses. Regularly monitoring and replacing hydraulic fluids can keep the system running smoothly. Additionally, optimizing the layout of hydraulic circuits to minimize bends and unnecessary fittings can enhance flow and reduce energy consumption, creating a more efficient operation overall.

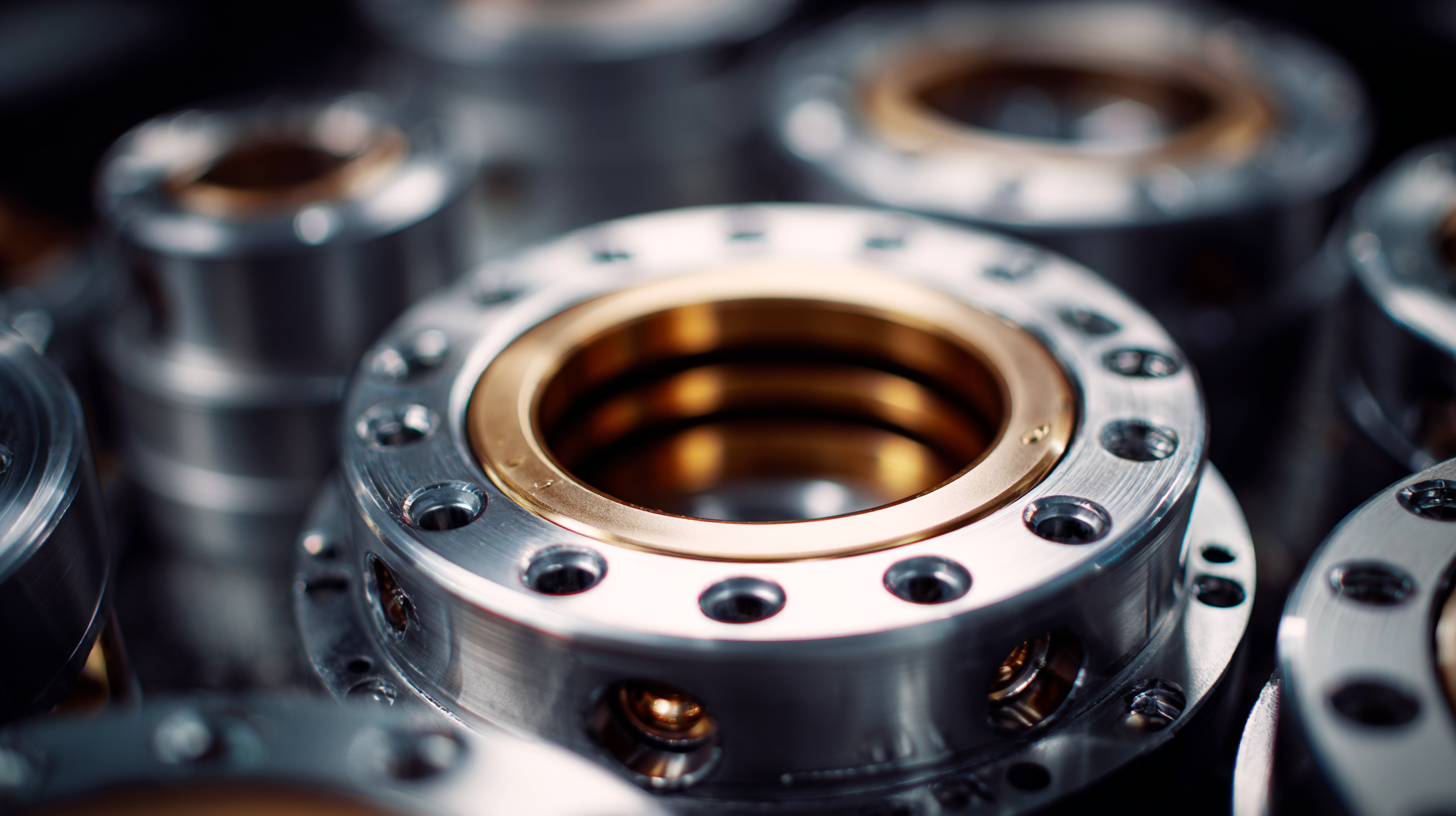

Hydraulic Parts Quality Comparison: China vs. Global

Industry Statistics: China's Position in the Global Hydraulic Parts Marketplace

China has firmly established itself as a dominant force in the hydraulic parts marketplace, evidenced by the impressive statistics reflecting its global sales. Recent studies indicate that Chinese manufacturers accounted for over 30% of the total global market share in hydraulic components, showcasing the country's ability to produce high-quality products at competitive prices. This remarkable growth is attributed to advancements in smart manufacturing technology, which not only enhances production efficiency but also ensures stringent quality control throughout the manufacturing process.

Moreover, China's strategic investments in research and development have further solidified its leadership position. By prioritizing innovation, Chinese companies are continuously improving the design and functionality of their hydraulic parts, making them highly sought after in various industries, including construction, agriculture, and automotive. The increasing demand for durable and efficient hydraulic systems around the world indicates a promising future for China's hydraulic parts sector, as it evolves to meet the needs of a rapidly changing marketplace.