How to Choose the Right Eaton Hydraulic Pump for Your Needs?

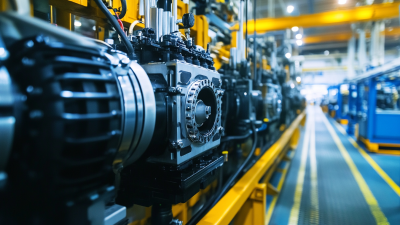

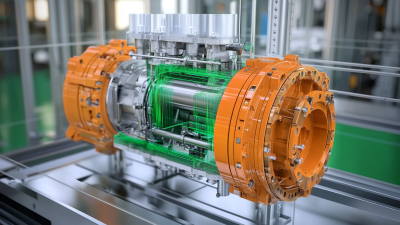

Choosing the right Eaton Hydraulic Pump is crucial for optimizing system performance in various applications. According to the Market Research Future report, the global hydraulic pump market is projected to grow significantly, reaching approximately $15 billion by 2027. This growth indicates the increasing reliance on hydraulic systems across industries such as construction, agriculture, and manufacturing.

Selecting an Eaton Hydraulic Pump involves understanding specific requirements. Factors like flow rate, pressure capabilities, and application type play essential roles. For instance, construction equipment often demands pumps that can endure heavy loads and provide consistent pressure. However, with numerous options available, users can feel overwhelmed. The market offers axial, radial, and gear types, each with unique advantages.

Not all Eaton Hydraulic Pumps are ideal for every scenario. Misjudging your need could result in inefficiencies. It’s important to evaluate not just specifications but also long-term maintenance needs. Doing so ensures proper functionality and reduces downtime in operations.

Factors to Consider When Selecting a Hydraulic Pump

Choosing the right hydraulic pump involves several crucial factors. It is essential to consider the flow rate needed for your application. Flow rate affects how efficiently your system operates. A pump that is too large can waste energy. Conversely, an undersized pump may fail to deliver the required power.

Additionally, think about pressure requirements. Each hydraulic system demands specific pressure levels. Ensure that the pump you select can handle these pressures. Ignoring this could lead to system failures. You should also evaluate the pump's compatibility with the fluid. The type of hydraulic fluid impacts pump performance and longevity.

Operating environment is another aspect to consider. Some pumps are better suited for harsh conditions. Assess the temperature and potential contaminants. Overlooking environmental factors could lead to rapid wear or failure. Sometimes, even minor details like reservoir size matter. A well-matched pump and reservoir promote efficient system operation. Be thoughtful about all these factors; they define the system's success.

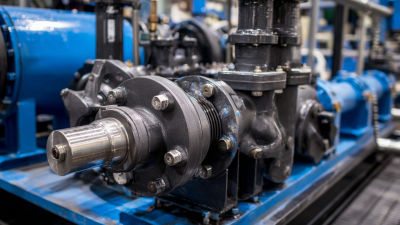

Types of Eaton Hydraulic Pumps and Their Applications

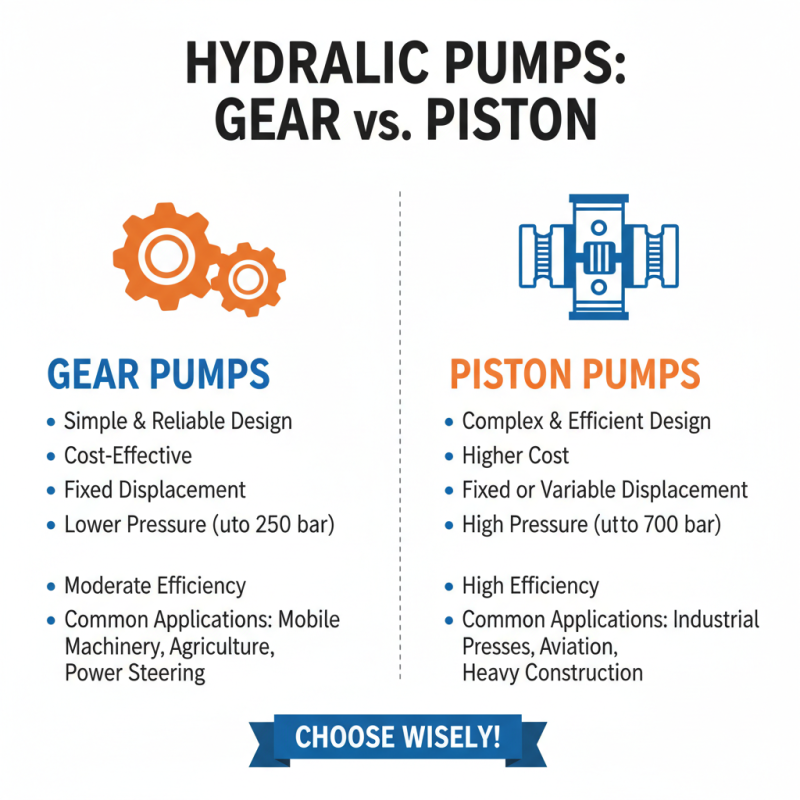

Choosing the right hydraulic pump can be challenging. Understanding the different types of hydraulic pumps is essential. Two common types are gear pumps and piston pumps. Gear pumps are reliable and simple. They work well in many applications, like mobile machinery. Piston pumps offer higher efficiency and variable flow. They are ideal for demanding tasks.

When selecting a pump, consider your specific needs. What will you use it for? Smaller, compact pumps are great for tight spaces. Larger systems may require more powerful pumps. Take time to analyze your application requirements.

**Tips:** Check the pump's pressure rating. Ensure it meets your system's needs. Also, assess the fluid compatibility. Using the wrong fluid can damage the pump.

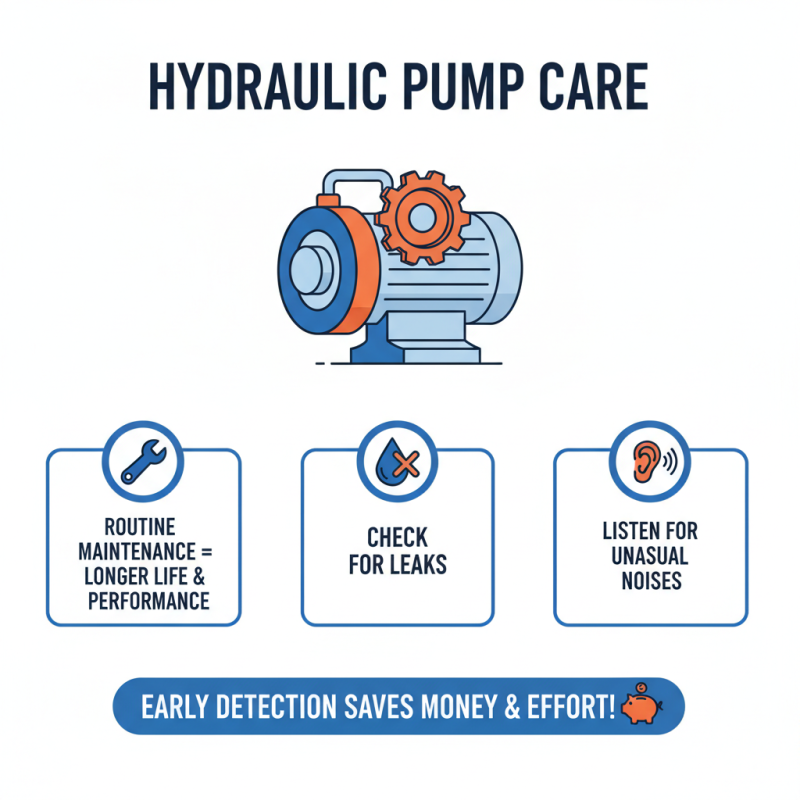

Maintenance plays a critical role in pump longevity. Regular inspections help spot issues early. Keep an eye on oil levels and look for leaks. Ignoring these can lead to costly repairs. Take a proactive approach to maintain your pump performance.

Understanding Flow Rate and Pressure Requirements

When choosing a hydraulic pump, understanding flow rate is essential. Flow rate determines how much fluid moves through the system. It's usually measured in gallons per minute (GPM) or liters per minute (LPM). A pump with too high a flow rate can cause issues, like excessive pressure or fluid loss. Conversely, too low a flow rate might not meet the demands of your system. Finding the right balance is crucial to ensure optimal performance.

Pressure requirements also play a significant role. The pump must generate enough pressure to overcome system resistance. This includes any restrictions in hoses, fittings, and valves. Insufficient pressure can lead to equipment failure. An unexpected pressure drop can disrupt operations and lead to costly downtime. Pay attention to the system’s characteristics when determining the required pressure.

It’s also important to consider the operating environment. High temperatures or contaminants can affect pump performance. Selecting a pump that can handle these conditions can be challenging. You might wonder if you can find a pump that balances all these factors. Sometimes, it feels like a guessing game. Testing and adjustments are often necessary to achieve the desired results.

Evaluating Environmental Conditions for Pump Selection

When selecting a hydraulic pump, environmental conditions play a crucial role. Temperature, humidity, and exposure to contaminants can greatly affect pump performance. For instance, a study by the Hydraulic Institute reveals that around 30% of pump failures are linked to environmental factors. Therefore, evaluating these conditions upfront can save costs and enhance efficiency.

Temperature variations can lead to changes in fluid viscosity. This can influence pump efficiency and longevity. In harsh environments, where temperatures exceed 100°F, special lubricants may be necessary. Likewise, high humidity can result in corrosion. An estimated 15% of hydraulic systems face issues due to moisture. Additionally, exposure to dust and other particles can decrease a pump's operational lifespan. Engaging with studies highlighting maintenance records may guide better choices.

The surrounding environment also dictates the type of seal and materials to use. For example, pumps in aggressive climates often require specialized coatings. This can prevent premature wear and extend service life. Data suggests that improperly sealed pumps fail 20% faster than well-maintained ones. Operators must reflect on these factors to ensure their systems remain reliable and efficient.

Maintenance and Support for Eaton Hydraulic Pumps

When it comes to maintaining hydraulic systems, proper care for your hydraulic pump is crucial. Routine maintenance extends the pump’s life and ensures optimal performance. Regularly check for leaks and unusual noises. These issues might indicate underlying problems. Addressing them early can save money and effort later.

Tips: Keep a maintenance log. Note down any irregularities you observe. This record can help diagnose issues over time. Also, make it a habit to clean the pump regularly. Dust and contaminants can lead to premature wear.

Support is equally important. Having access to expert help can make a difference. Sometimes, the manufacturer's support may be limited. In that case, seek third-party professionals who specialize in hydraulic systems. They can provide valuable insights and aid in complex repairs.

Tips: Don't hesitate to ask for help. Gather information from various sources. Compare maintenance practices and support options. This research might reveal best practices that you hadn't considered before. Engaging with a community of users can also provide new perspectives and solutions.

Related Posts

-

Amidst US-China Tariff Challenges, China's Eaton Hydraulic Pump Production Surges: A Statistical Insight

-

5 Essential Tips for Optimizing Your Pump Parts Purchasing Process

-

Unlocking the Benefits of Efficient Tractor Hydraulic Pumps for Your Agricultural Needs

-

Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types

-

2025 Innovations in Hydraulic Pumps: Transforming Efficiency and Sustainability in Industrial Applications

-

Troubleshooting Common Issues in Hydraulic Parts: A Global Procurement Perspective