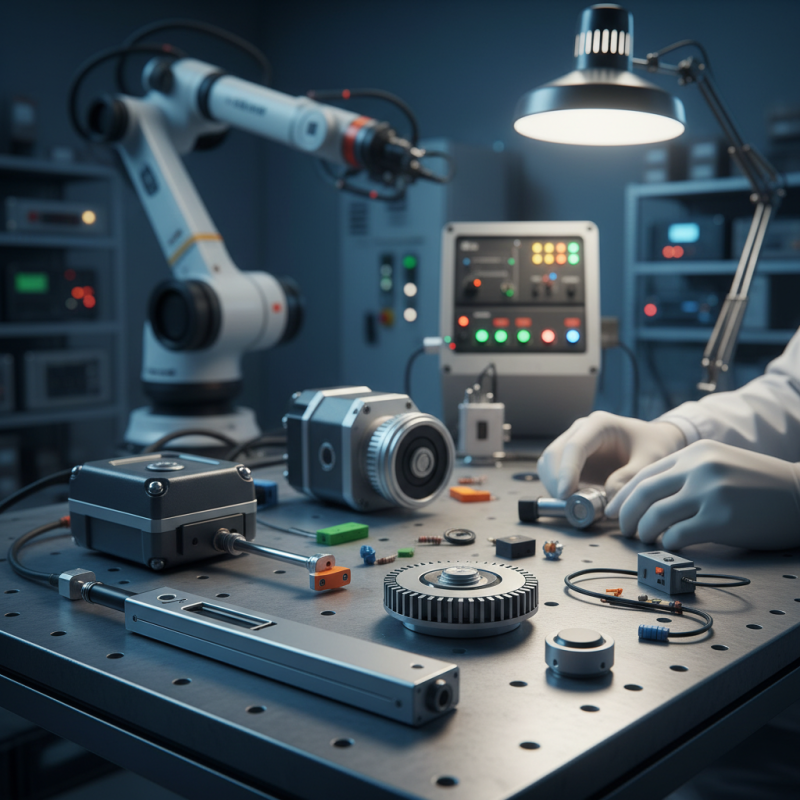

How to Choose the Right Position Sensor for Your Application?

In today's highly automated world, choosing the right Position Sensor is crucial for ensuring precision and reliability. Dr. Emily Carter, an expert in sensor technology, states, "The success of any application often relies on the quality of its position sensor." This statement underscores the importance of selecting the appropriate sensor tailored to specific needs.

Position sensors come in various types, each serving unique applications. For example, linear position sensors are ideal for measuring straight-line motion, while rotary sensors excel in applications requiring angular measurement. However, the decision-making process is not always straightforward. Factors such as environmental conditions, required accuracy, and compatibility can complicate the selection. Often, users might overlook these details, leading to unexpected challenges.

Moreover, the market is constantly evolving, with new technologies emerging frequently. Keeping up with these advancements can be overwhelming. It’s easy to make impulsive choices when faced with numerous options. However, reflecting on one's specific requirements can prevent costly mistakes. Ultimately, choosing the right position sensor is about aligning its capabilities with your application's demands.

Understanding the Different Types of Position Sensors and Their Applications

When choosing a position sensor, understanding the types available is crucial. There are several types in the market. Each type serves specific purposes. Examples include linear, rotary, and magnetic sensors. Linear sensors measure straight-line movement. They're often used in industrial automation.

Rotary sensors are different. They monitor rotational movement. This makes them ideal for robotics and motor control. Magnetic sensors utilize magnetic fields to detect movement. They are often compact, fitting well in tight spaces. Each sensor has strengths and weaknesses. For instance, rotary sensors might face accuracy issues in high-speed applications.

It's essential to assess your application’s needs carefully. Think about range, precision, and environment. Factors like temperature and humidity influence performance. Not all sensors are perfect for every situation. It's okay to make mistakes in the selection process. Learning from those errors can lead to better choices in the future. Testing different sensors can provide insights on what truly works for your setup.

Key Specifications to Consider When Selecting a Position Sensor

When selecting a position sensor for your application, key specifications play a crucial role. One important specification is accuracy. According to the industry report by Ams AG, positional accuracy can vary by up to 0.001 inches for certain precision applications. This level is vital in sectors such as robotics and aerospace. Ignoring accuracy requirements may lead to errors that compromise performance and safety.

Another critical factor is range. Position sensors offer varying ranges, from a few millimeters to several meters. A study from the International Journal of Advanced Manufacturing Technology highlights that choosing a sensor with too limited a range can hinder operational flexibility. If your equipment moves beyond the specified range, it could cause irreversible damage or downtime. Conversely, overestimating the range may lead to unnecessary costs.

Environment is also a significant consideration. Sensors must withstand factors like moisture, temperature fluctuations, and physical impact. The same report mentions that exposure to harsh conditions can reduce lifespan by nearly 30%. Thus, assessing the environment is essential for sensor longevity. It’s easy to overlook these environmental factors, but doing so might result in frequent replacements or malfunctions that could have been avoided.

Evaluating Environmental Factors Impacting Position Sensor Performance

When selecting a position sensor, environmental factors play a crucial role. Humidity, temperature, and exposure to chemicals can significantly affect the sensor's performance. For instance, high humidity levels can cause corrosion. This might lead to inaccurate readings or sensor failure over time. Extreme temperatures can impact the response time and reliability of the sensor.

Tips: Consider the location of the sensor. Is it in a dry or humid area? Understanding the environment is key. Take into account any potential exposure to dust or contaminants. These can greatly influence sensor functionality.

Another important factor is vibration. In industrial settings, equipment often operates under constant movement. This can disrupt a sensor's accuracy. Choose a sensor designed to withstand vibrations. Always assess how your specific application might expose the sensor to varying conditions. This reflection will guide your selection process.

Environmental Factors Impacting Position Sensor Performance

Comparing Cost and Performance Trade-offs in Position Sensor Technologies

When selecting a position sensor, cost and performance are key factors. Different technologies offer varying benefits and drawbacks. For example, potentiometers are often cheaper but may lack long-term stability. On the other hand, magnetic sensors provide robustness but can be pricier. Each application requires careful consideration of these trade-offs.

Cost is not the sole factor. Performance is crucial too. An inaccurate sensor can lead to costly mistakes. Some sensors may perform well in stable environments but fail in more dynamic settings. Reflecting on this, it's essential to assess the specific needs of the application. Will high precision justify a higher cost?

Additionally, the installation environment matters. Harsh conditions can affect sensor life. Choosing a less expensive sensor could result in frequent replacements. This may increase costs in the long run. By weighing these elements, you can make a more informed decision.

How to Choose the Right Position Sensor for Your Application? - Comparing Cost and Performance Trade-offs in Position Sensor Technologies

| Sensor Type | Cost (USD) | Accuracy (mm) | Range (mm) | Speed (m/s) | Environment Suitability |

|---|---|---|---|---|---|

| Potentiometer | 20 - 50 | 0.5 | 0 - 100 | 1 | Indoor |

| Linear Variable Differential Transformer (LVDT) | 100 - 300 | 0.01 | 0 - 500 | 0.5 | Indoor/Outdoor |

| Capacitive Position Sensor | 50 - 150 | 0.1 | 0 - 300 | 0.8 | Indoor |

| Optical Encoder | 150 - 400 | 0.001 | 0 - 360 | 5 | Indoor/Outdoor |

| Magnetic Position Sensor | 30 - 80 | 0.5 | 0 - 200 | 2 | Indoor/Outdoor |

Best Practices for Integrating Position Sensors into Your Systems

Integrating position sensors effectively requires careful consideration. The sensor's type, range, and accuracy must align with application needs. Industry reports indicate that up to 30% of sensor failures occur due to improper installation. Ensuring compatibility is crucial. For instance, using capacitive sensors in environments with high humidity may lead to erroneous readings.

When implementing position sensors, rigorous testing is essential. Regular calibration can mitigate issues caused by sensor drift. Research shows that 25% of technical failures are linked to inadequate calibration practices. Engineers should also document the integration process. This practice fosters better communication and troubleshooting later.

Additionally, consider environmental factors. Temperature and vibration can significantly affect sensor performance. Deploying protective casing often mitigates these risks. However, costs may rise, requiring a balance between investment and reliability. Ultimately, an iterative approach to integration helps refine sensor placements and improves overall effectiveness.