Understanding the Efficiency of Mixer Pumps in Modern Industrial Applications

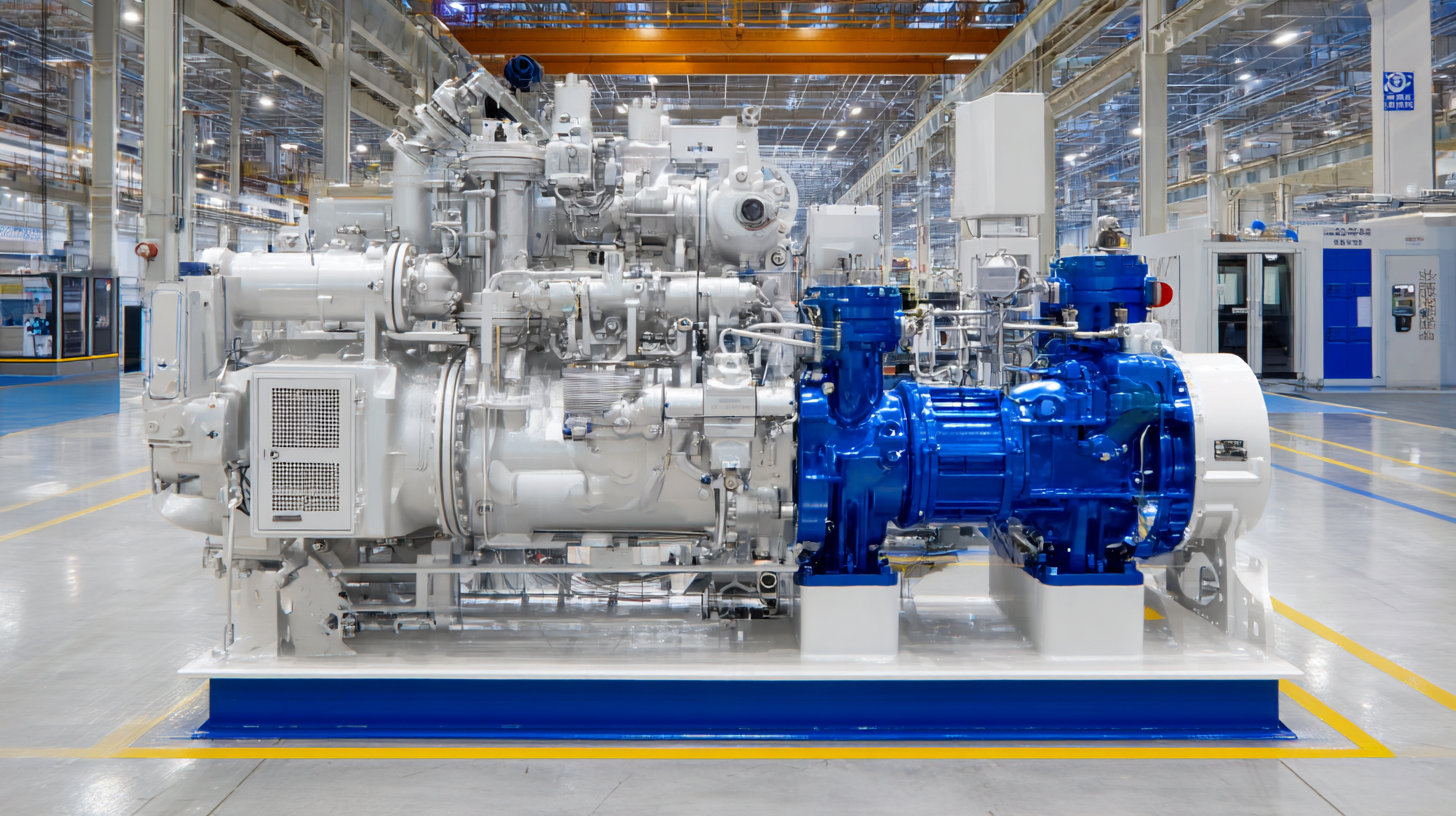

In the contemporary industrial landscape, the role of advanced machinery is pivotal for enhancing operational efficiency and productivity. Among these innovations, the Mixer Pump stands out due to its unique ability to combine the functions of mixing and pumping fluids simultaneously. This device is particularly indispensable in various sectors, including construction, agriculture, and wastewater management, where the need for homogeneous mixtures is critical.

By understanding the intricate design and operational principles of Mixer Pumps, industries can leverage their capabilities to improve workflow, reduce labor costs, and ensure consistent product quality. This exploration delves into the mechanics of Mixer Pumps, highlighting their advantages, applications, and the technological advancements that have propelled them to the forefront of modern industrial applications.

By understanding the intricate design and operational principles of Mixer Pumps, industries can leverage their capabilities to improve workflow, reduce labor costs, and ensure consistent product quality. This exploration delves into the mechanics of Mixer Pumps, highlighting their advantages, applications, and the technological advancements that have propelled them to the forefront of modern industrial applications.

The Role of Mixer Pumps in Enhancing Production Efficiency in Manufacturing Processes

Mixer pumps play a pivotal role in enhancing production efficiency within various manufacturing processes. By integrating mixing and pumping operations, these machines streamline workflows and reduce the need for additional equipment. This not only saves valuable space on the factory floor but also minimizes operational costs. In industries where precise material consistency is crucial, mixer pumps ensure that the blending of liquids and solids occurs uniformly, thus safeguarding the quality of the final product.

Tips: To maximize the efficiency of mixer pumps, regularly maintain and inspect the equipment. Ensure proper calibration for specific production requirements, as well as monitor the viscosity and temperature of materials being processed. Tailoring the pump settings to the unique demands of each application can significantly boost overall productivity and reduce waste.

Furthermore, the versatility of mixer pumps allows them to adapt to different industrial needs. Whether used in pharmaceuticals, food processing, or construction, these machines contribute to faster production cycles. Tips: Consider investing in advanced mixer pump technologies that enable real-time monitoring and automation. This not only enhances operational efficiency but also provides valuable data for continuous improvement initiatives. Embracing these innovations can lead to considerable advancements in manufacturing efficiency.

Comparative Analysis of Mixer Pump Performance Across Various Industrial Applications

Mixer pumps play a crucial role in various industrial applications, effectively blending materials while ensuring consistent flow rates. Their performance can vary significantly across different sectors, influenced by factors such as viscosity, density, and the nature of the substances being mixed. For instance, mixer pumps used in the chemical industry require robust designs to handle corrosive materials, whereas those in the food industry must comply with strict hygiene standards. A comparative analysis reveals that performance metrics such as energy efficiency, mixing time, and maintenance needs can differ widely based on these applications.

Mixer pumps play a crucial role in various industrial applications, effectively blending materials while ensuring consistent flow rates. Their performance can vary significantly across different sectors, influenced by factors such as viscosity, density, and the nature of the substances being mixed. For instance, mixer pumps used in the chemical industry require robust designs to handle corrosive materials, whereas those in the food industry must comply with strict hygiene standards. A comparative analysis reveals that performance metrics such as energy efficiency, mixing time, and maintenance needs can differ widely based on these applications.

Tips: When selecting a mixer pump, consider the specific requirements of your application. It's essential to assess the fluid characteristics, desired mixing time, and compatibility with materials to ensure optimal performance. Regular maintenance checks can also significantly enhance the lifespan and efficiency of mixer pumps, preventing costly downtimes.

Additionally, industries such as construction and wastewater management rely on mixer pumps for effective slurry handling. The comparative analysis of pump performance in these sectors highlights the importance of tailored engineering designs that cater to unique operational challenges. By leveraging innovative technologies, manufacturers can enhance mixer pump efficiency, resulting in improved productivity and lower operational costs.

Tips: Always consult with experts when integrating mixer pumps into your systems. Understanding the nuances of each application will help in selecting the right pump and optimizing overall operational efficiency.

Key Technical Specifications for Optimal Mixer Pump Functionality and Efficiency

Mixer pumps play a pivotal role in various industrial applications, necessitating an understanding of their key technical specifications for optimal functionality and efficiency. The mixer's design should allow for precise control of flow rates and mixing intensities, ensuring that materials are homogeneously combined. Parameters such as impeller design, motor power, and pump placement directly influence the mixing process, impacting overall productivity and quality of the output.

Another critical specification is the viscosity of the materials being processed. Mixer pumps must be capable of handling substances with varying viscosities, which requires robust engineering and adaptability in design. Additionally, factors such as temperature control mechanisms and energy consumption rates are essential for maximizing efficiency. By carefully considering these specifications, industries can select the most suitable mixer pumps to enhance their operations, reduce downtime, and improve energy efficiency, ultimately leading to more sustainable production practices.

Industry Trends: Adoption Rates and Innovations in Mixer Pump Technology

The adoption of mixer pump technology has witnessed significant growth in recent years, primarily driven by advancements in industrial processes and the increasing need for efficiency. According to a report by MarketsandMarkets, the global mixer pump market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This surge is partly attributed to enhanced blending capabilities and the rising demand in sectors like construction, food and beverage, and pharmaceuticals.

Innovations in mixer pump technology have also played a crucial role in this trend. The integration of IoT and smart technologies into mixer pumps allows for real-time monitoring and control, leading to improved performance and energy efficiency. A study conducted by the American Society of Mechanical Engineers (ASME) found that facilities utilizing smart mixer pumps reported a 30% reduction in operational costs. Such advancements not only streamline workflow processes but also ensure better product quality and consistency, making them indispensable in modern industrial applications.

Maximizing ROI: Evaluating the Cost-Benefit of Using Mixer Pumps in Industrial Settings

In modern industrial applications, the efficiency of mixer pumps plays a pivotal role in enhancing productivity and maximizing return on investment (ROI). A recent market study indicates that the integration of variable frequency drives (VFDs) with mixer pumps can improve energy efficiency by up to 30%, reducing operational costs significantly. In industries where precise fluid blending is essential, such as dairy processing, the right configuration of pumps and valves not only ensures optimal performance but also aligns with sustainability goals, which are increasingly prioritized in today's manufacturing landscape.

Evaluating the cost-benefit of using mixer pumps reveals that although the initial investment may appear substantial, the long-term savings and operational efficiency often outweigh these costs. Industry reports suggest that companies utilizing advanced mixer pumping solutions can expect to see their operational costs decrease by as much as 20% over five years. This figure highlights that investing in high-quality pumps and valves is not merely an expenditure but a strategic move toward enhancing production capacities and improving overall profitability in industrial settings.

Related Posts

-

What Makes a Mixer Pump Essential for Modern Industry

-

Understanding the Science Behind Mixer Pumps: Essential Guide for Efficient Fluid Management

-

2025 Hydraulic Drives Trends and 7 Key Innovations Shaping the Future

-

Troubleshooting Common Issues in Hydraulic Parts: A Global Procurement Perspective

-

7 Key Reasons Why Hydraulic Pump Parts Are Essential for Operational Efficiency

-

Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types