5 Essential Tips for Optimizing Your Pump Parts Purchasing Process

The efficiency and effectiveness of industrial operations often hinge on the quality and reliability of pump parts, as they play a critical role in various processes across multiple sectors. According to a report by the Hydraulic Institute, pump maintenance and replacement can account for up to 20% of a facility's total operational costs, emphasizing the need for optimized purchasing strategies. In an industry where downtime can lead to substantial revenue losses—averaging around $22,000 per hour for unplanned outages—it becomes paramount for businesses to streamline their pump parts procurement process.

By following essential tips for optimizing purchases, companies can not only reduce costs but also enhance the operational lifespan of their equipment, thereby driving efficiency and productivity in the long run.

Identifying Key Requirements for Pump Parts Procurement

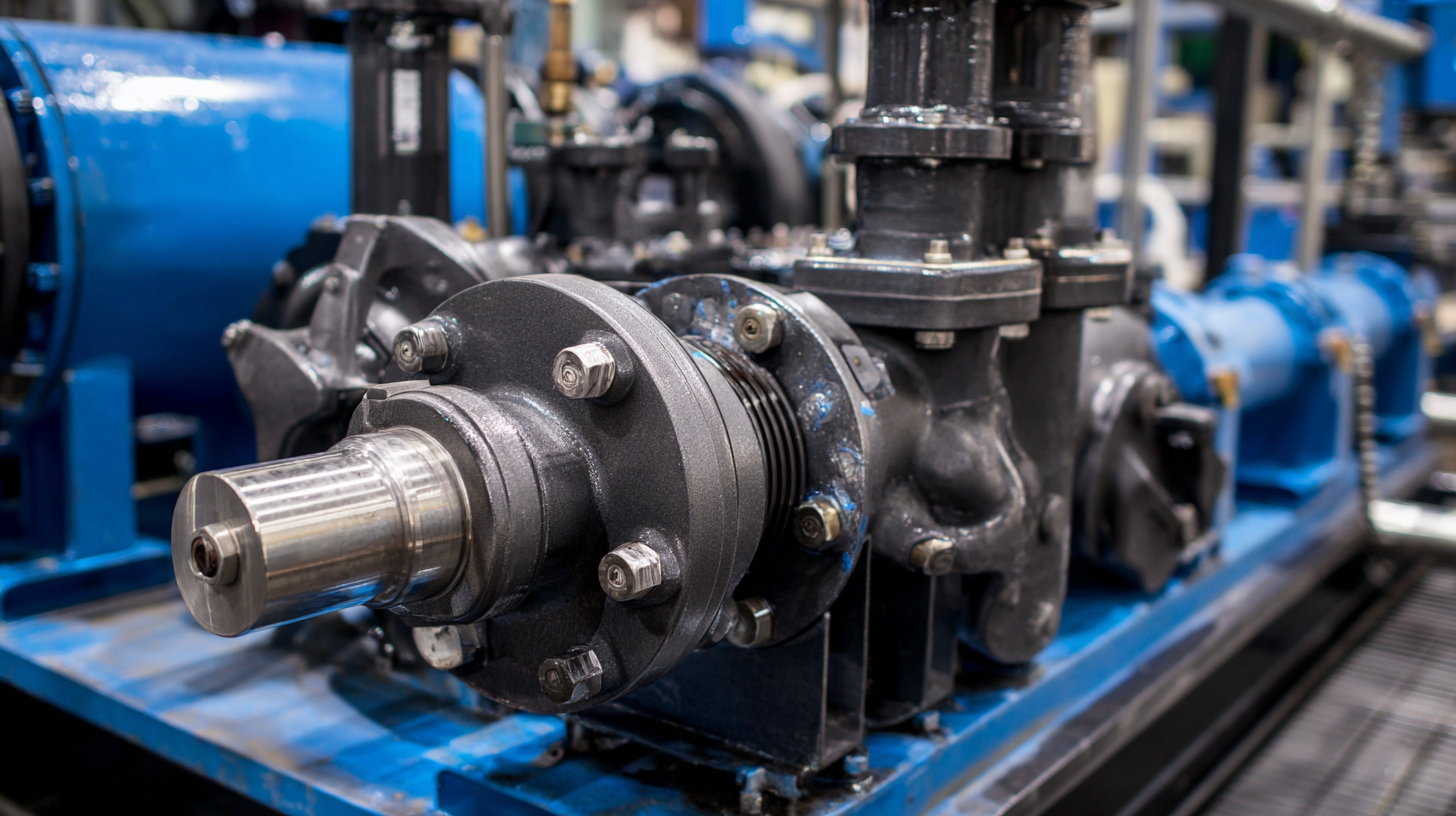

When it comes to the procurement of pump parts, identifying key requirements is essential for streamlining the purchasing process. Start by understanding the specific needs of your application. Consider factors such as the type of fluid being pumped, temperature and pressure conditions, and the expected lifespan of the components. Engaging with engineering teams can help clarify these needs, ensuring that the parts selected will perform reliably under operational stresses.

Next, establish a thorough specification sheet that outlines all technical criteria, including material compatibility, size, and performance standards. This document serves as a valuable reference during the procurement phase, allowing for accurate comparison of products from different suppliers. Additionally, involving multiple stakeholders—such as maintenance and procurement teams—can foster a collaborative approach, ensuring all perspectives are considered. This comprehensive understanding of your requirements not only facilitates a smoother purchasing process but also contributes to the overall efficiency and reliability of your pumping systems.

5 Essential Tips for Optimizing Your Pump Parts Purchasing Process

| Tip | Description | Key Considerations | Benefits |

|---|---|---|---|

| 1. Define Specifications | Clearly outline the requirements for pump parts to ensure compatibility and performance. | Material, dimensions, pressure ratings | Reduces miscommunication and errors in purchasing. |

| 2. Evaluate Suppliers | Assess potential suppliers based on quality, reliability, and track record. | Certification, customer reviews, delivery times | Ensures high-quality parts and timely delivery. |

| 3. Optimize Inventory Management | Implement a system for tracking inventory levels and forecasting needs. | Usage patterns, lead times, reorder points | Reduces stockouts and overstock issues. |

| 4. Negotiate Terms | Discuss payment terms, bulk discounts, and return policies with suppliers. | Volume purchases, payment flexibility | Improves cash flow and reduces costs. |

| 5. Establish a Review Process | Regularly review purchasing strategies and supplier performance. | Performance metrics, feedback solicitation | Ensures continuous improvement and cost-effectiveness. |

Researching and Selecting Reliable Suppliers for Pump Components

When it comes to optimizing your pump parts purchasing process, researching and selecting reliable suppliers for pump components is crucial. A supplier's reputation can significantly impact the quality and durability of the parts you acquire. Start by gathering recommendations from industry peers or through online forums, as firsthand experiences often reveal the strengths and weaknesses of various suppliers. Once you have a list of potential suppliers, delve into their client reviews and case studies to understand their track record in delivering high-quality products.

When it comes to optimizing your pump parts purchasing process, researching and selecting reliable suppliers for pump components is crucial. A supplier's reputation can significantly impact the quality and durability of the parts you acquire. Start by gathering recommendations from industry peers or through online forums, as firsthand experiences often reveal the strengths and weaknesses of various suppliers. Once you have a list of potential suppliers, delve into their client reviews and case studies to understand their track record in delivering high-quality products.

Another important aspect is to consider the supplier’s certifications and compliance with industry standards. This not only ensures that the components meet safety and performance benchmarks but also reflects the supplier’s commitment to maintaining quality. Moreover, communication is key; assess how responsive the supplier is to inquiries and their willingness to provide technical support. A supplier that is proactive in addressing your concerns can be a valuable partner in your pump parts purchasing journey, ensuring a smooth and efficient procurement process.

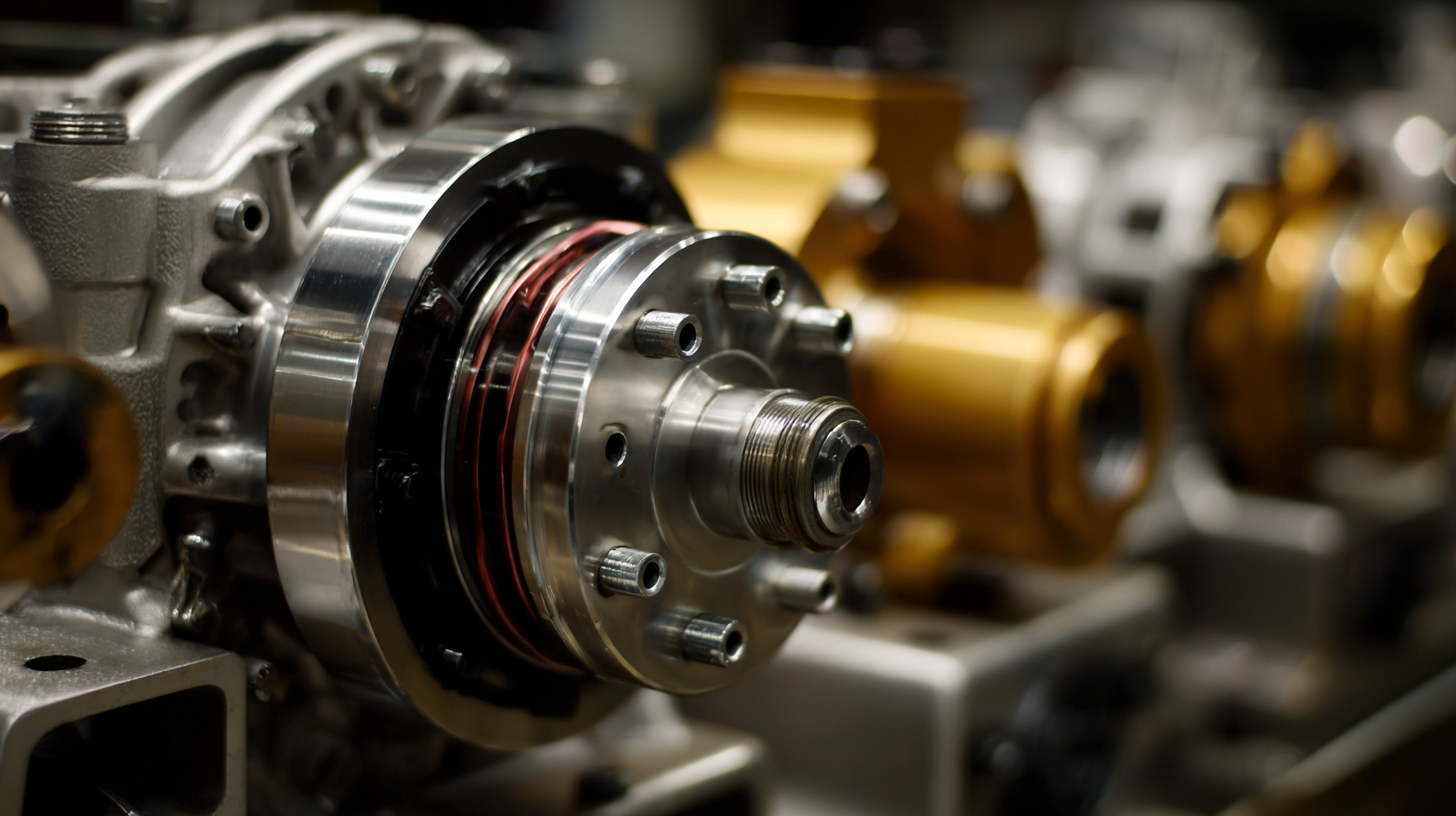

Evaluating Cost-Effectiveness and Quality in Pump Parts Buying

When it comes to purchasing pump parts, evaluating cost-effectiveness and quality is paramount. To achieve this balance, start by conducting thorough market research to compare different suppliers. This will allow you to not only assess prices but also understand the quality standards they uphold. Look for reviews and testimonials from other buyers, as they can provide valuable insights into the reliability of the parts and the supplier's service quality.

Another essential tip is to establish a clear understanding of your needs. Analyze the specific requirements of your pumping systems to avoid overspending on unnecessary features. Focus on sourcing parts that provide optimal performance for your application while ensuring they meet industry standards. Additionally, consider engaging with suppliers who offer warranties or guarantees on their products, as this assures you of their commitment to quality.

Lastly, don't forget to leverage technology in your purchasing process. Utilizing inventory management software can streamline your order tracking and help you identify when it's time to reorder parts. This not only saves time but can also lead to better negotiations with suppliers, as you'll have a clear understanding of your purchasing patterns and needs, enabling you to advocate for more favorable pricing and terms.

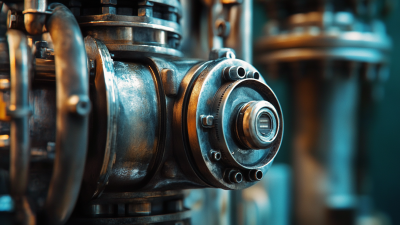

Streamlining the Order Process for Faster Delivery of Pump Parts

In the competitive landscape of pump parts purchasing, streamlining the order process is paramount for ensuring faster delivery and maximizing customer satisfaction. Incorporating efficient last-mile delivery strategies can significantly enhance the overall purchasing experience. This focuses not only on warehouse efficiency but also on how well orders are dispatched and delivered directly to the end-user. By optimizing the logistics involved in the final leg of delivery, businesses can meet the increasingly high expectations set by customers for rapid fulfillment.

To achieve this, implementing an integrated order management system can provide real-time tracking and transparency throughout the purchasing process. This technology allows businesses to monitor inventory levels, manage orders efficiently, and ensure that pump parts are dispatched promptly. Additionally, fostering strong relationships with reliable delivery partners can enhance shipping capabilities, ensuring that customers receive their orders on time. In a market where customers demand quick and efficient service, prioritizing these strategies in your pump parts purchasing process can set your business apart and lead to increased customer loyalty.

Implementing Regular Reviews and Feedback for Continuous Improvement

In today’s competitive landscape, organizations must prioritize continuous improvement through regular reviews and feedback loops. Implementing a structured process for gathering and analyzing feedback not only enhances service quality but also drives alignment with business objectives. According to a systematic review on employee performance, effective feedback mechanisms can improve operational efficiency by up to 30%, highlighting the importance of integrating these practices into the purchasing process for pump parts.

To optimize your purchasing process, consider these tips:

- First, establish a robust feedback system that regularly assesses supplier performance and product quality. This will ensure that any issues are identified early, facilitating timely adjustments.

- Second, implement regular reviews of your purchasing criteria and processes. By staying flexible and responsive to feedback, companies can adapt swiftly to market changes and enhance overall purchasing efficiency.

- Lastly, leverage technology to automate feedback collection and analysis, streamlining the process and reducing human error.

Related Posts

-

How to Choose the Best Pump Parts for Optimal Efficiency and Longevity in Your Operations

-

Unlocking the Benefits of Efficient Tractor Hydraulic Pumps for Your Agricultural Needs

-

Ultimate Hydraulic Repair Checklist for Optimal Performance

-

Ultimate Checklist for Sourcing the Best Hyd Pumps for Your Projects

-

Revolutionizing Industrial Efficiency with Advanced Hydraulic Drives in Global Markets

-

Innovative Pump Technology Leading Global Market Trends in Efficiency and Sustainability