Unlocking the Benefits of Hydraulic Drives: A Global Sourcing Guide

The global hydraulic drives market is poised for significant growth, driven by the increasing demand for efficient and powerful machinery across various industries. According to a report by MarketsandMarkets, the hydraulic drive systems market is projected to reach USD 20.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.1% from 2020 to 2025. The rising adoption of automation in manufacturing processes and the need for energy-efficient solutions are key factors fueling this expansion. Hydraulic Drives play a crucial role in enhancing operational efficiency, providing robust power transmission for applications in construction, agriculture, and industrial machinery.

Furthermore, the growing emphasis on sustainability and reducing carbon footprints has catalyzed innovations in hydraulic technology. Research from the International Hydraulics Association indicates that hydraulic systems can achieve up to 90% energy efficiency, outperforming traditional mechanical systems. This transition towards hydraulic drives not only improves performance but also aligns with global sustainability goals. As industries look to source reliable hydraulic solutions to meet these demands, understanding the advantages and intricacies of hydraulic drives becomes essential for making informed sourcing decisions.

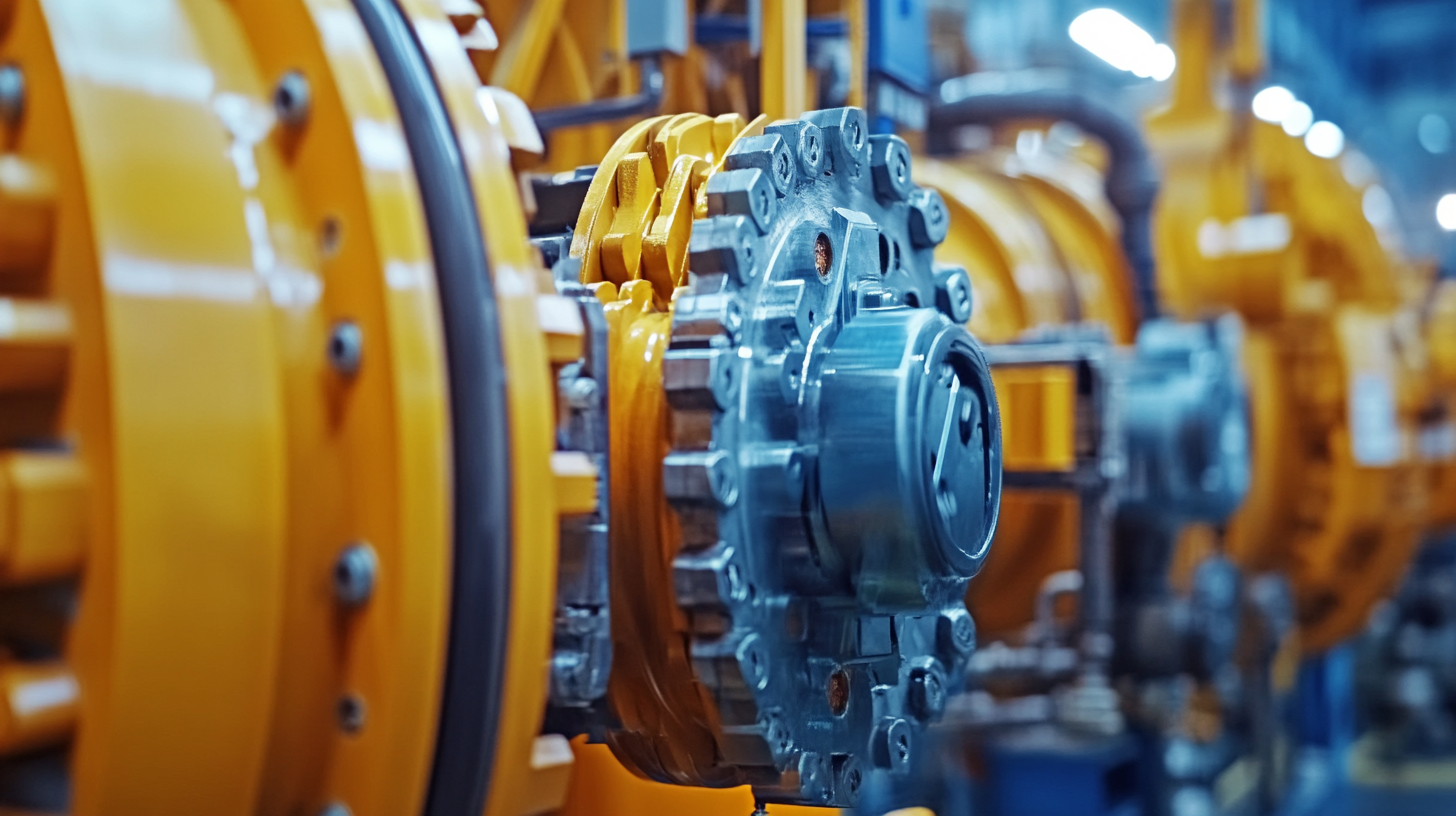

Understanding Hydraulic Drives: Key Components and Mechanisms

Hydraulic drives are increasingly recognized for their efficiency and power transmission capabilities across various industries. Understanding the key components and mechanisms of these systems is crucial for maximizing their benefits. At the heart of a hydraulic drive system are several essential components, including hydraulic pumps, actuators, and accumulators. According to a recent report by Grand View Research, the global hydraulic equipment market is projected to reach $59.1 billion by 2025, underscoring the growing reliance on hydraulic technology in industrial applications. Hydraulic pumps are responsible for converting mechanical energy into hydraulic energy, enabling the movement of fluids within the system. A typical configuration includes gear, vane, and piston pumps, each offering distinct advantages depending on the operational demands. For instance, piston pumps are favored in high-pressure applications due to their efficiency and durability. The capability of hydraulic drives to generate high torque at low speeds makes them particularly appealing for heavy-duty applications such as construction and mining. According to the International Fluid Power Society, hydraulic actuators can provide force levels up to five times greater than their electromechanical counterparts, making them indispensable in scenarios requiring substantial power output. Another critical element of hydraulic drives is the hydraulic actuator, which translates hydraulic energy into mechanical movement. These actuators can include both linear and rotary types, allowing for a wide range of applications from industrial machinery to aerospace systems. The versatility of hydraulic drives is backed by a report from Research and Markets, indicating that the hydraulic actuators market alone is expected to grow at a CAGR of 5.9% from 2020 to 2025. This growth reflects the ongoing innovation and efficiency improvements that hydraulic technology continues to offer, solidifying its role as a foundational element in modern engineering solutions.

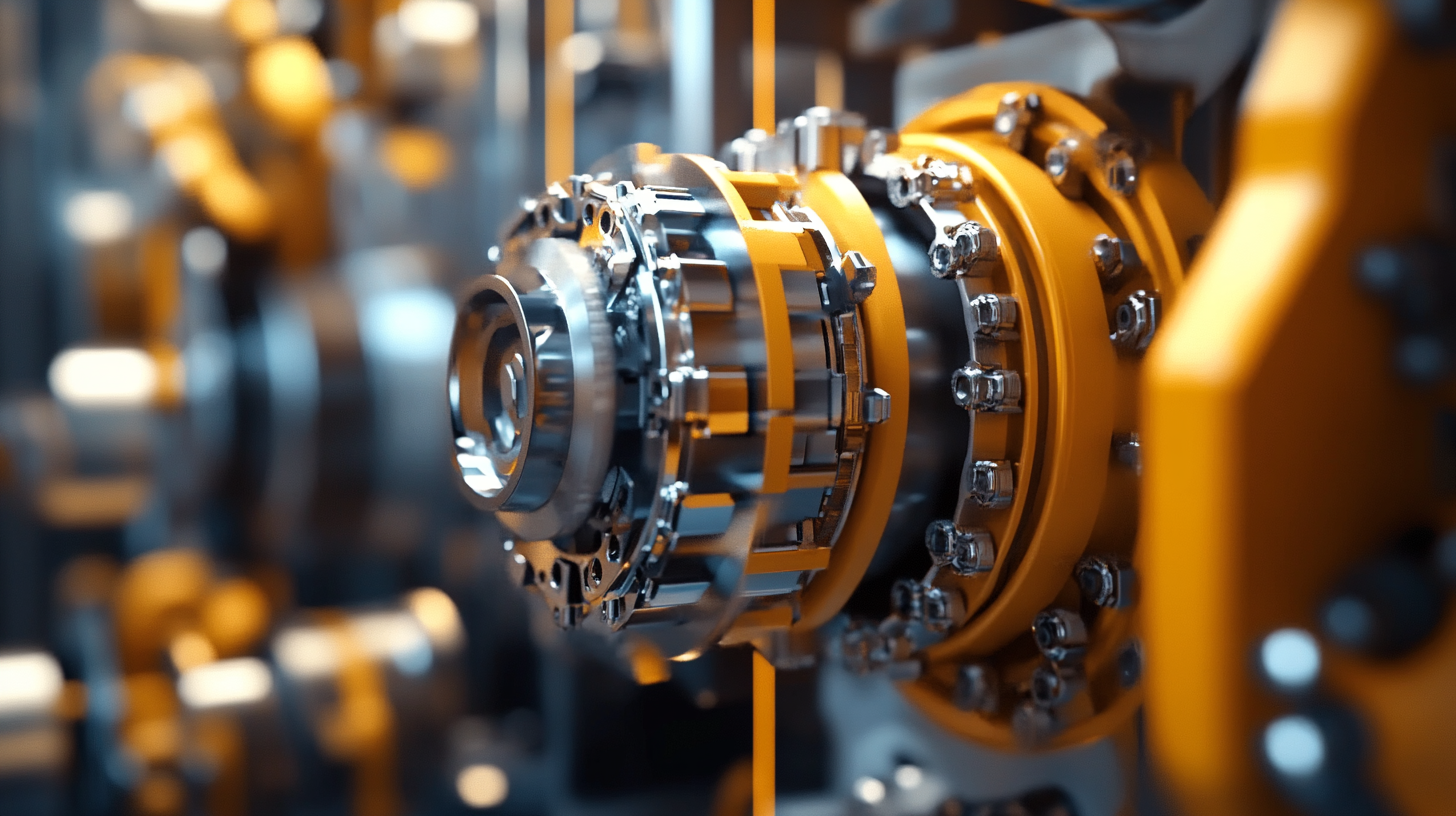

The Advantages of Hydraulic Drives Over Traditional Systems

Hydraulic drives have long been lauded for their robust performance and efficiency, but recent advancements reveal even more significant advantages over traditional systems. One of the most compelling benefits is the seamless integration of hydraulic technology with smart controls and sensors, which enhances system performance monitoring. Ongoing research into sensor technologies is leading to more reliable and precise operations, facilitating better management of hydraulic systems. This synergy enables predictive maintenance and real-time system adjustments, ensuring optimal performance and longevity of hydraulic components.

Moreover, as industries prioritize sustainability, hybrid systems such as Quantum's electric/hydraulic power system are emerging, leveraging the strengths of traditional hydraulics while incorporating cleaner, electric elements. This innovation not only improves energy efficiency but also meets the evolving performance demands of various applications, from aerospace to maritime. The combination of hydraulic power density with electric technology creates a pathway towards smarter and more sustainable machines, addressing both operational efficiency and environmental concerns.

The transition from traditional pneumatic and hydraulic systems to hybrid and electrical actuators is particularly evident in the aerospace and defense sectors. These industries, traditionally dominated by hydraulic power, are seeing a shift as the advantages of electric technologies come to the forefront. The integration of servo technology and intelligent control systems is leading to hydrauliс systems that offer unparalleled controllability, significantly enhancing operational capabilities while reducing energy expenditures. This evolving landscape not only underscores the advantages of hydraulic drives but also reflects a broader trend towards innovation and efficiency in fluid power applications.

Global Sourcing Strategies for Hydraulic Drive Components

In today's rapidly evolving industrial landscape, the global sourcing of hydraulic drive components has become increasingly critical. With the industrial hydraulic equipment market projected to grow significantly, reaching USD 52.6 billion by 2033, companies need to adopt effective global sourcing strategies to enhance their competitiveness. The adoption of common architecture and a standardized product portfolio can streamline processes, reduce costs, and foster top-line growth. This systematic approach not only simplifies supplier management but also facilitates the integration of innovative solutions to meet the evolving demands of various sectors.

As industries embrace modularity, global sourcing of hydraulic drive components allows for flexibility and scalability in operations. Companies can leverage regional suppliers to minimize lead times and improve responsiveness while ensuring quality and compliance with international standards. This strategy enables businesses to remain agile in the face of market fluctuations and technological advancements. Moreover, investing in partnerships with key manufacturers can accelerate access to cutting-edge technology and expertise, further driving innovation in hydraulic systems and components.

Additionally, with the growing emphasis on sustainability and energy efficiency, sourcing teams must consider sustainable practices and eco-friendly materials in their procurement processes. By integrating these considerations into their sourcing strategies, companies can not only meet regulatory requirements but also enhance their brand reputation and long-term viability in an increasingly competitive market. With the hydraulic drive market on the rise, adopting forward-thinking global sourcing strategies is essential for companies to unlock their full potential and thrive in the industrial sector.

Evaluating Quality and Reliability in Hydraulic Drive Suppliers

When embarking on the quest for hydraulic drive suppliers, the evaluation of quality and reliability is paramount. A hydraulic drive system's performance heavily depends on the components used, making it essential to partner with suppliers who uphold stringent manufacturing standards. It’s crucial to inquire about certifications, such as ISO 9001, as they indicate adherence to quality management principles and consistent delivery of high-quality products. A well-established supplier will not only provide evidence of their compliance with such standards but also demonstrate their commitment to continuous improvement in their processes.

In addition to certifications, assessing the reliability of a supplier involves scrutinizing their track record and customer feedback. Successful suppliers often showcase case studies or testimonials that reflect their ability to meet deadlines and manage projects effectively. Engaging directly with previous clients can yield insights into the supplier's responsiveness to issues and willingness to provide support throughout the lifecycle of the product. This information is invaluable when determining whether a supplier will offer the dependability and service level your business requires.

Another factor to consider is the supplier’s technological capabilities and innovation in hydraulic drive solutions. A supplier that invests in research and development is more likely to provide cutting-edge products that enhance performance and efficiency in your operations. By evaluating the blend of quality certifications, customer testimonials, and technological proficiency, businesses can confidently select hydraulic drive suppliers that not only meet their immediate needs but also align with long-term operational goals.

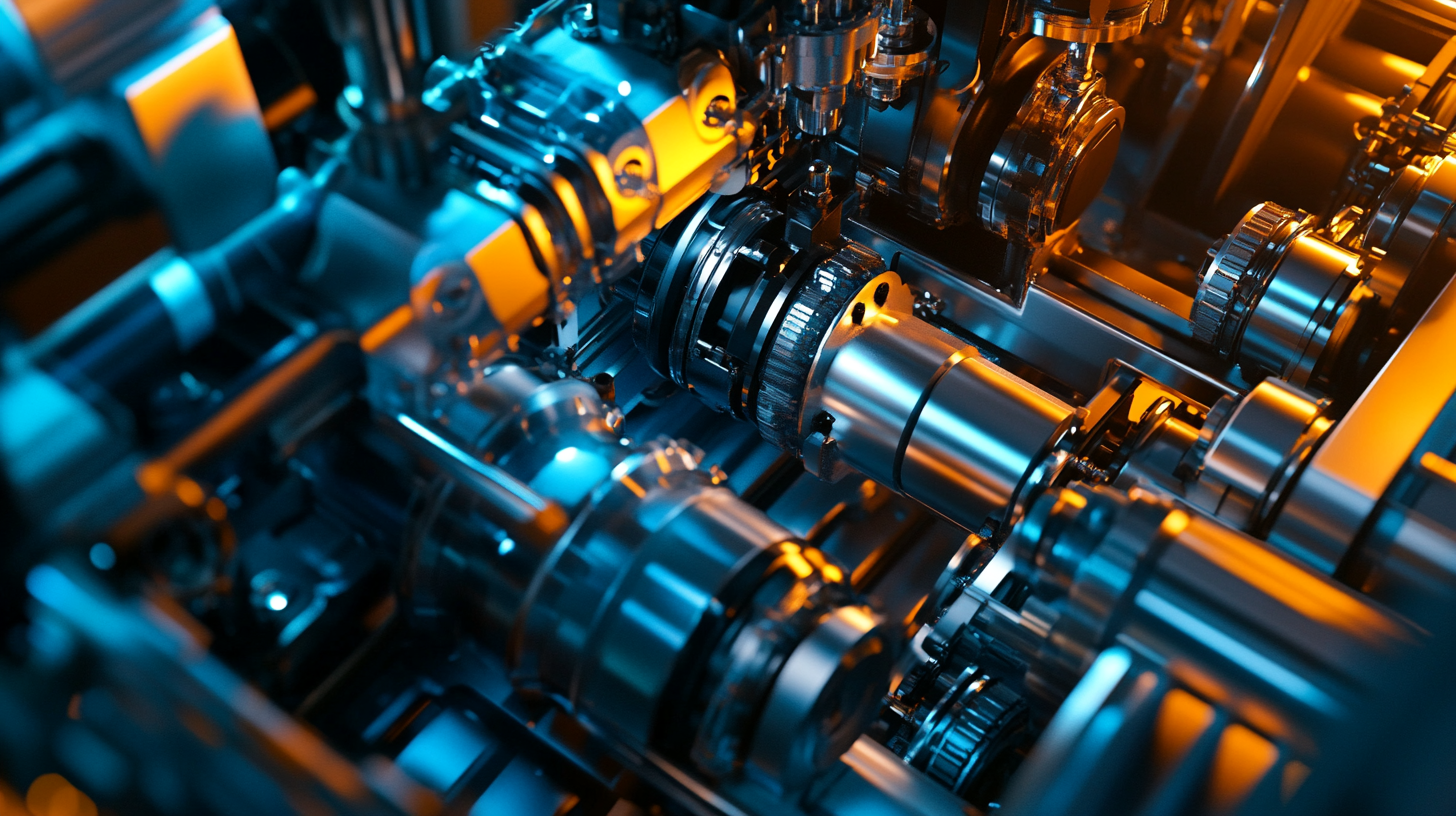

Future Trends in Hydraulic Drive Technology and Sourcing Solutions

The landscape of hydraulic drive technology is evolving rapidly, driven by innovations that not only enhance performance but also improve sustainability. As industries worldwide increasingly recognize the importance of energy efficiency and environmental responsibility, hydraulic systems are being designed to meet these demands. Future trends indicate a shift towards more compact, lightweight designs that incorporate smart technologies, enabling real-time monitoring and control. This advancement allows for optimal performance and reduces energy waste, making the systems not only more efficient but also more reliable.

In addition to technological advancements, sourcing solutions are becoming more globalized. Manufacturers are seeking suppliers that not only provide high-quality components but also contribute to the entire lifecycle management of hydraulic systems. This includes offering support in maintenance, serviceability, and adaptability to new technologies. Companies that provide integrated solutions—encompassing design, sourcing, and setelah-sales support—are positioning themselves as key players in the hydraulic drive market. By leveraging international supply chains, businesses can enhance their resilience to market fluctuations and access innovative products that improve their operational efficiency.

As hydraulic drive technology continues to evolve, companies that stay ahead of these trends will be better equipped to meet the demands of a competitive marketplace. Embracing advancements in technology and adopting a proactive approach to sourcing will be crucial for businesses aiming to unlock the full potential of hydraulic drives and harness their benefits for future success.