What is an Injection Machine Robot and How Does It Work?

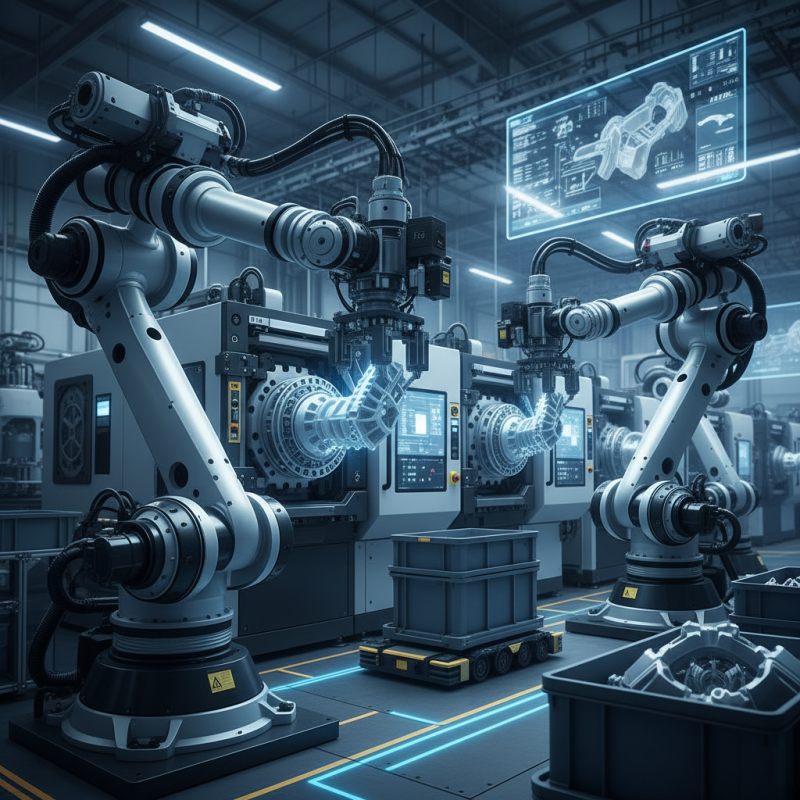

An Injection Machine Robot is a remarkable tool in modern manufacturing. These robots automate the injection molding process. They bring efficiency, precision, and speed to production lines. Many industries rely on them for various plastic components.

The technology behind an Injection Machine Robot is fascinating. It uses advanced programming and sensors to monitor each step. This ensures that every part meets strict quality standards. However, implementing such robots can be challenging. The initial setup costs are high. Training staff to operate and maintain them requires time and resources.

Despite their advantages, there are concerns. Some worry about job displacement in factories. Others question the long-term reliability of robots. While these machines excel in consistency, occasional malfunctions can occur. Manufacturers must continuously assess the balance between human oversight and robotic efficiency.

What is an Injection Machine Robot?

An injection machine robot is a sophisticated piece of technology used in manufacturing. It automates the injection molding process, which creates various plastic products. These robots work by precisely injecting molten plastic into molds. Once the material cools, the mold is removed, resulting in a finished part.

These robots come in different sizes and configurations, designed to fit various production needs. They improve efficiency and reduce waste, but they can require significant initial investment. Often, programming them can be complex, and operators may need training. Mistakes can happen, especially with intricate designs, leading to production delays.

Despite the challenges, the benefits are clear. Productivity can soar when using injection machine robots. They can operate continuously and handle repetitive tasks well. However, if a mold breaks or a malfunction occurs, the entire system may halt. This highlights the need for regular maintenance and monitoring to prevent issues. Balancing automation with human oversight remains an ongoing reflection in modern manufacturing.

Injection Machine Robot Usage Statistics

Key Components of an Injection Machine Robot

Injection machine robots are crucial in modern manufacturing. They automate the process of injecting molten materials into molds. This ensures precision and efficiency. Understanding their key components can enhance their functionality.

One vital component is the hopper. It feeds raw materials into the machine. A reliable hopper prevents jams, ensuring smooth operation. Another important part is the injection unit. This unit melts the materials and injects them into molds. The speed and pressure of injection are critical. Inadequate settings may result in defects.

The clamping unit holds the mold tightly during injection. A weak clamp can lead to leaks and wasted materials. Sensors and controllers also play a significant role. They monitor temperature, pressure, and timing. If these elements fail to communicate effectively, production can halt.

Regular maintenance is essential. It helps identify potential issues before they disrupt operations. These components work together, but they require attention to detail for success.

How Injection Machine Robots Operate: Step-by-Step Process

Injection machine robots are essential for modern manufacturing. They streamline the production of plastic parts through a method called injection molding. Understanding how these machines operate can shed light on their effectiveness and efficiency.

The process begins with the robot picking up a pre-defined mold. This is usually a two-part cavity. After that, plastic pellets are fed into a heated barrel. Here, the pellets melt into a liquid form. Once the plastic is ready, the injection robot pushes it into the mold with great force. This creates the desired shape. After a short cooling period, the mold opens up, and the newly formed part is ejected.

Throughout this operation, precision is key. Any misalignment can ruin the part. The robot must move with speed and accuracy. However, challenges can arise, like improper cooling or inconsistent pressure. Operators often need to monitor these factors closely. Small variations can lead to defects, which require scrapping parts or reworking them. The technology is impressive, but not infallible. Continuous improvements are necessary for better outcomes.

Applications of Injection Machine Robots in Manufacturing

Injection machine robots are revolutionizing the manufacturing sector. These robots automate the injection molding process, enhancing production efficiency. According to a report by the International Federation of Robotics, the market for industrial robots is expected to grow by 10% annually. This surge is largely driven by the need for precision in manufacturing. With specifications of tolerances often in the micrometers, injection machine robots are capable of achieving high levels of accuracy.

In various industries, the applications of these robots are vast. They are particularly prominent in automotive, consumer goods, and electronics production. The automotive sector alone accounted for over 30% of robot installation worldwide in 2022. This highlights their crucial role in modern production lines. However, not all companies have successfully integrated these robots. Some face challenges, including high initial costs and training requirements. This can lead to delays in productivity gains, reflecting a need for strategic planning.

Furthermore, these robots can handle complex tasks. For instance, they can operate multiple injection points simultaneously, minimizing cycle times. This capability often leads to increased output, but it can overwhelm existing systems. Companies may struggle to keep pace with maintenance and calibration needs. Adjusting to such a change requires careful consideration and adaptation. The transition to automation may be challenging, but the potential benefits are undeniable.

What is an Injection Machine Robot and How Does It Work? - Applications of Injection Machine Robots in Manufacturing

| Application | Description | Benefits | Industries |

|---|---|---|---|

| Automotive Parts Manufacturing | Injection robots are used to manufacture various plastic parts for vehicles. | High precision, speed, and reduced labor costs. | Automotive |

| Consumer Electronics | Used to create housings and components like remote controls and phone cases. | Improved manufacturing efficiency and lower material waste. | Consumer Electronics |

| Medical Devices | Production of surgical tools, syringes, and other medical components. | Enhanced cleanliness and accuracy in delicate manufacturing processes. | Healthcare |

| Packaging | Used to manufacture components for containers, bottles, and caps. | Cost efficiency and high-volume production capabilities. | Food & Beverage |

| Toys | Injection molding for producing various plastic toys and components. | Fast production rates and complex design possibilities. | Toys & Games |

Benefits of Using Injection Machine Robots in Production Lines

Injection machine robots are revolutionizing production lines. They automate the injection molding process, increasing efficiency and precision. This technology reduces human error and speeds up production cycles. With these robots, manufacturers can handle complex tasks that might overwhelm human workers. They operate tirelessly, maintaining high output levels.

One significant benefit is reduced waste. Injection machine robots minimize material loss during molding. They ensure consistent quality, which is often challenging in manual processes. Additionally, these robots free human workers from monotonous tasks. This shift allows employees to focus on more strategic roles. However, the transition may require retraining staff and adapting workflows. Companies must carefully assess their integration strategies. Balancing automation with human labor is crucial for optimal results.