Mastering Hydraulic Pumps: A Step-by-Step Guide for Global Buyers

In today's fast-paced industrial landscape, understanding the intricacies of hydraulic pumps is crucial for global buyers seeking efficient solutions for their operational needs. As the demand for reliable hydraulic systems continues to rise across various sectors, mastering the selection and utilization of hydraulic pumps becomes pivotal. This guide aims to empower decision-makers with the essential knowledge required to navigate the complexities of hydraulic pumps, ensuring that they choose the right solutions tailored for their specific applications.

From exploring the different types and functionalities of hydraulic pumps to offering practical tips on procurement, this step-by-step approach will equip buyers with the insights needed to enhance their operational efficiency and maximize their investment in hydraulic technology. Join us on this journey to demystify hydraulic pumps and unlock their full potential for your business.

Understanding Different Types of Hydraulic Pumps and Their Unique Benefits

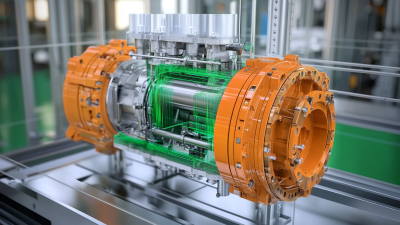

When exploring different types of hydraulic pumps, understanding their unique benefits is crucial for making informed purchasing decisions. Hydraulic pumps, particularly variable displacement piston pumps, have seen significant advancements, particularly in their design. A recent innovation features digitally controlled systems that enhance efficiency while minimizing noise—an essential factor in applications requiring quieter operation. These developments not only meet industry demands but also support a broader trend towards more sustainable and efficient hydraulic solutions.

Moreover, product differentiation plays a vital role in the hydraulic pump market, significantly impacting brand loyalty and competitive advantage. Companies can leverage unique features of their hydraulic pumps to establish a strong niche in the market. According to industry reports, brands that successfully communicate their product's distinct advantages can experience a notable increase in customer retention and sales. Value-based pricing strategically positions these products to reflect consumer perceptions of value, thereby boosting profitability.

As the market evolves, it becomes increasingly important to segment audiences effectively. By breaking down the diverse customer base, manufacturers can tailor their marketing efforts and product offerings to meet the specific needs of different segments. For instance, understanding the distinct requirements of industries such as construction or agriculture can guide the development of targeted hydraulic pump solutions, ultimately leading to better customer satisfaction and loyalty.

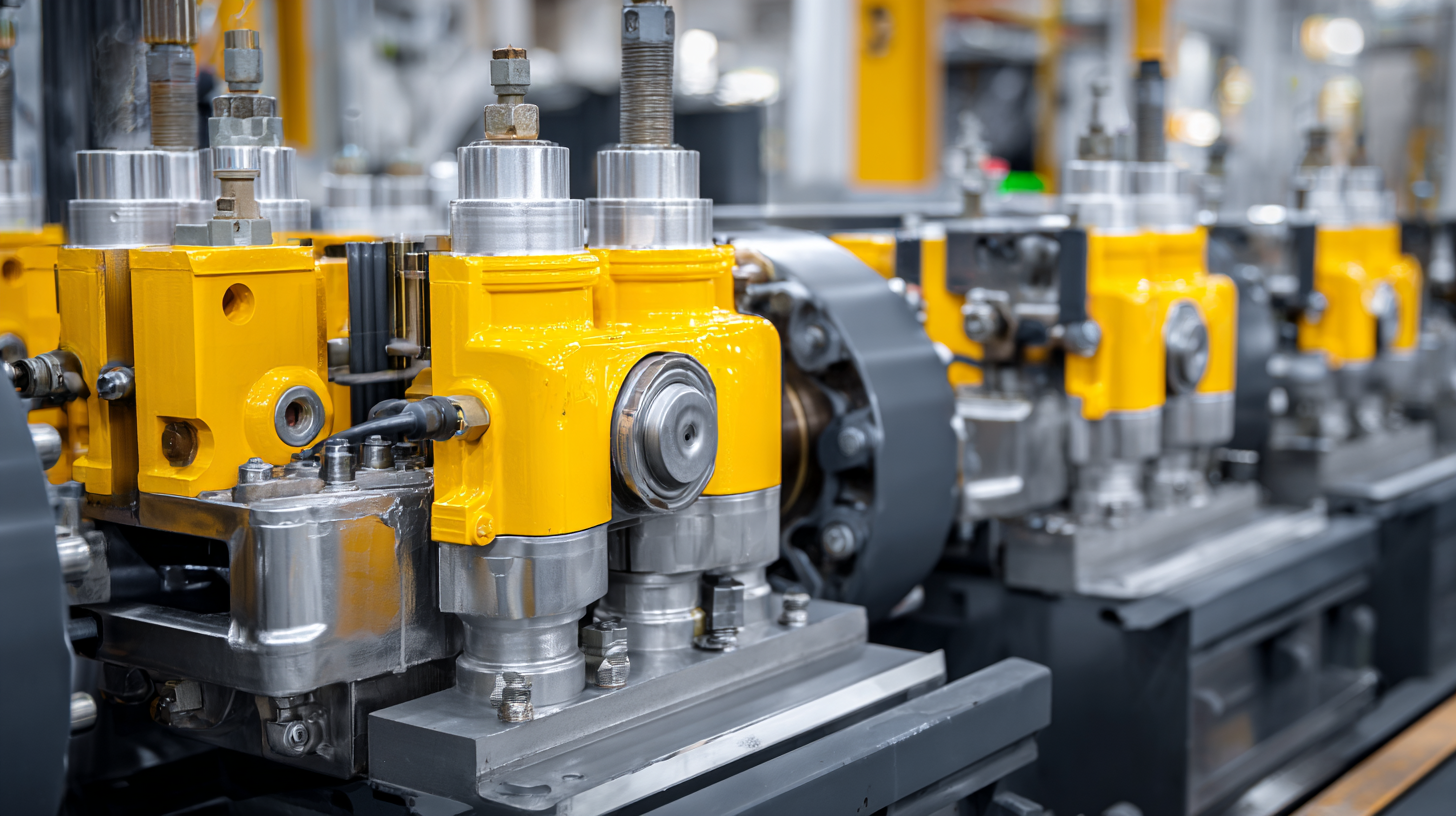

Hydraulic Pump Types and Their Unique Benefits

Key Advantages of Gear Pumps for Specific Applications

Hydraulic gear pumps are widely recognized for their efficiency and reliability, particularly in heavy-duty applications. According to a recent report by the International Fluid Power Society, gear pumps account for approximately 60% of the global hydraulic pump market, highlighting their critical role in various industries, including construction, agriculture, and manufacturing. Their design, characterized by two or more gears that mesh together, allows for consistent and smooth fluid transfer, making them ideal for applications that require precise control and high pressure.

One of the key advantages of gear pumps lies in their versatility. They can handle a wide range of viscosities and are particularly effective with low to medium viscosity fluids. A study published in the Journal of Hydraulic Engineering indicates that gear pumps can maintain a high volumetric efficiency of over 90%, making them preferred choices for hydraulic systems where space and weight are at a premium. Additionally, their simple construction translates into lower maintenance needs and reduced operational downtime, which is essential for industries where performance and reliability are paramount. This combination of efficiency and durability positions gear pumps as a leading option for global buyers seeking to optimize their hydraulic systems.

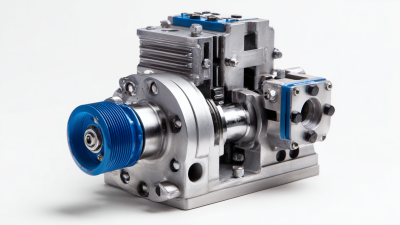

Exploring the Benefits of Piston Pumps in High-Pressure Environments

In high-pressure environments, the choice of hydraulic pump can significantly impact operational efficiency and equipment longevity. Piston pumps stand out as a preferred option due to their robust design and ability to deliver consistent and reliable performance, even under extreme conditions. Unlike gear pumps, which can struggle with pressure fluctuations, piston pumps utilize a series of reciprocating pistons to generate high pressure, ensuring a smooth and stable output. This characteristic makes them particularly valuable in industries such as mining, construction, and manufacturing, where persistent high demands are the norm.

One of the key benefits of piston pumps is their adaptability to varying operational requirements. With the ability to achieve higher pressure levels compared to other pump types, piston pumps ensure optimal performance in situations that require precise control, such as hydraulic cylinders or applications involving heavy machinery. Additionally, they tend to have a longer lifespan due to their sturdier construction, reducing downtime and maintenance costs. As global buyers delve into the world of hydraulic pumps, recognizing the advantages of piston pumps in high-pressure applications could lead to more informed purchasing decisions and ultimately improve productivity and efficiency across various sectors.

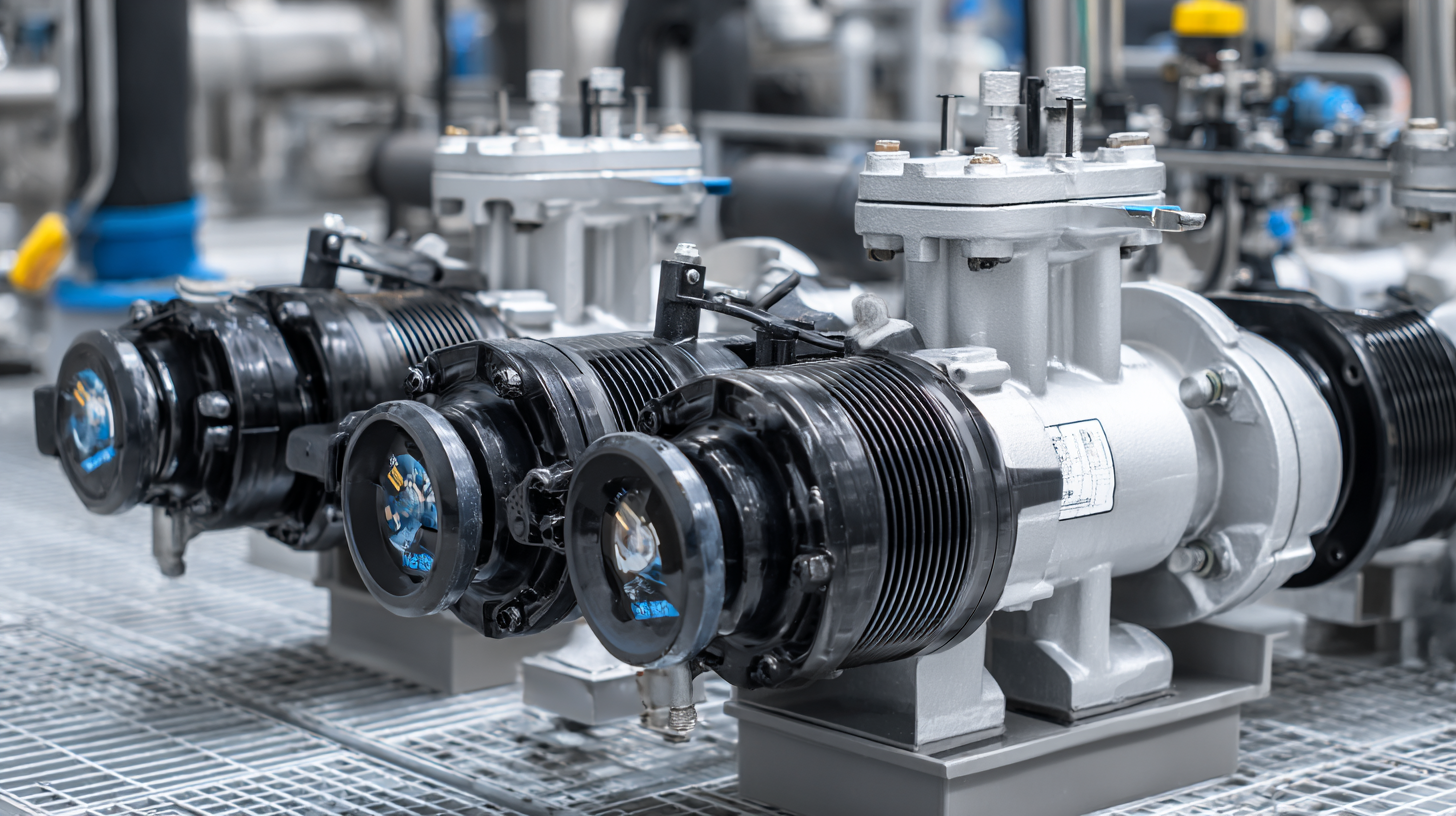

The Efficiency and Versatility of Vane Pumps in Industrial Settings

Vane pumps have emerged as a pivotal component in various industrial applications due to their unparalleled efficiency and versatility. As the global landscape for laboratory vacuum pumps is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2025 to 2034, reaching an estimated value of USD 1.8 billion by 2024, industries are increasingly relying on these pumps for precise fluid handling. Their design enables effective fluid dynamics, making them ideal for settings requiring consistent and reliable performance.

Additionally, advanced hydraulic fluids, such as fire-resistant options, are gaining traction in the industrial sector. These fluids are engineered to minimize fire risks while enhancing system efficiency and reducing wear on hydraulic equipment. This evolution in fluid technology complements the operational capabilities of vane pumps, making them a preferred choice for environments that prioritize safety and efficiency. As industries continue to adapt and innovate, the integration of high-performing pumps and superior hydraulic fluids will be essential for optimizing operational productivity.

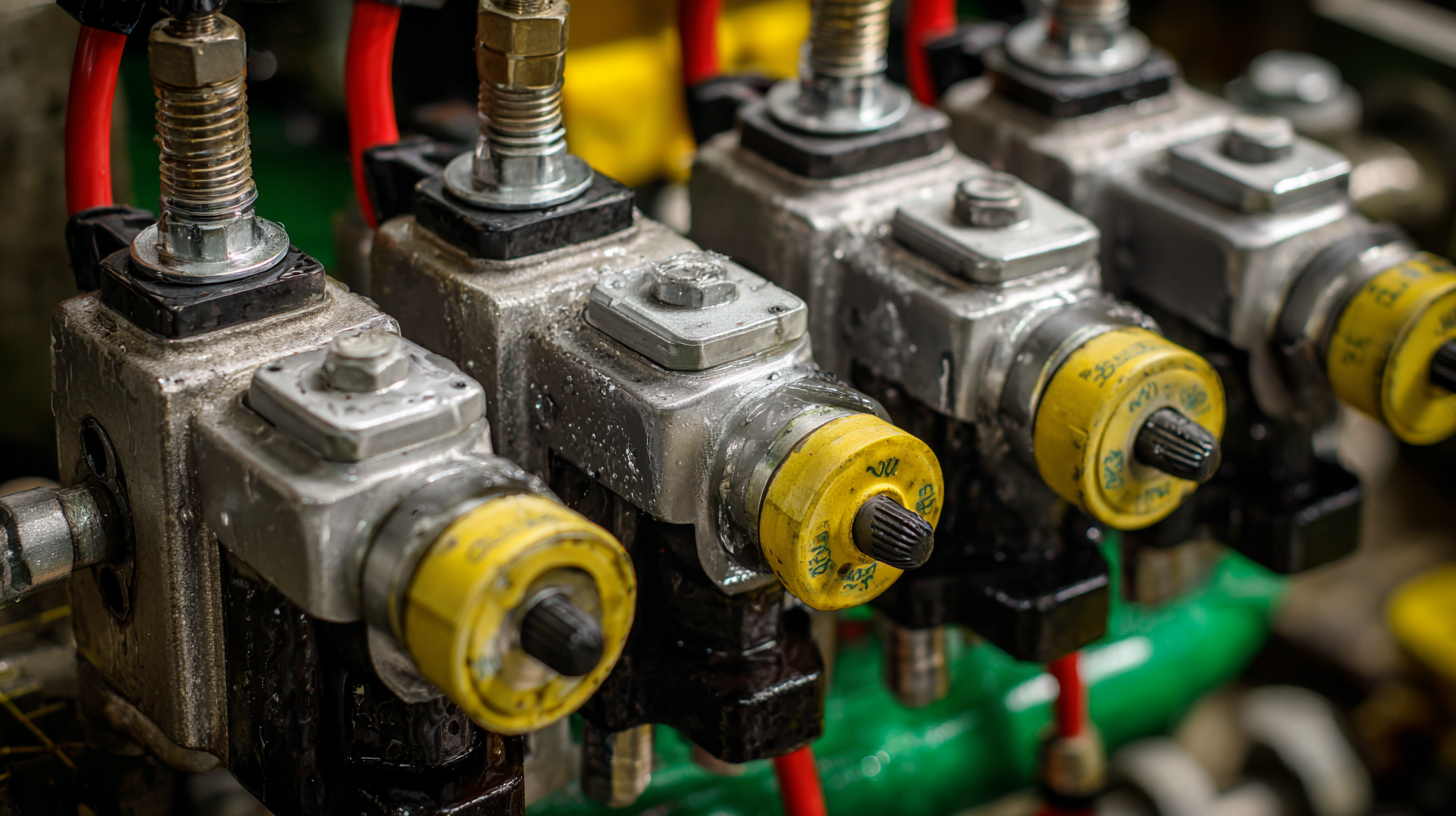

Cost-Effectiveness and Maintenance Benefits of Diaphragm Pumps for Global Buyers

When considering cost-effectiveness and maintenance benefits in the realm of hydraulic pumps, diaphragm pumps emerge as a standout choice for global buyers. These systems are not only known for their reliability but also for their ability to handle a wide range of fluids, including corrosive and viscous materials. Their design minimizes leakage, leading to reduced waste and lower overall operational costs. This makes diaphragm pumps particularly appealing to industries seeking to enhance their sustainability initiatives while maintaining operational efficiency.

As the metering pumps market continues to expand, projected to reach USD 8.5 billion by 2028, the growing demand emphasizes the need for businesses to invest in high-quality, cost-effective hydraulic solutions. Diaphragm pumps play a pivotal role in this growth, offering significant maintenance advantages. With fewer moving parts compared to other pump types, they require less frequent servicing, translating to decreased downtime and increased productivity. By integrating diaphragm pumps into their operations, global buyers can ensure not only financial savings but also a more resilient and efficient pumping system that meets the demands of today’s dynamic industrial landscape.

Related Posts

-

Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types

-

15 Reasons Why Best Hyd Pumps Are Essential for Your Business Success

-

Future Trends in Best Hydraulic Pump Market Analysis for 2025 Business Growth Insights

-

2025 Innovations in Hydraulic Pumps: Transforming Efficiency and Sustainability in Industrial Applications

-

Ultimate Checklist for Sourcing the Best Hyd Pumps for Your Projects

-

Innovative Pump Technology Leading Global Market Trends in Efficiency and Sustainability