Top Strategies for Maximizing Efficiency with the Best Hydraulic Machine in Your Industry

In today's fast-paced industrial landscape, maximizing efficiency is crucial for maintaining a competitive edge. According to a report by the International Fluid Power Society, hydraulic machines account for approximately 30% of all machinery used in various sectors, laying the groundwork for operational success. The versatility of hydraulic machines makes them indispensable in industries ranging from construction to manufacturing. As technology continues to evolve, understanding how to leverage the capabilities of these powerful tools is essential. This tutorial will delve into the top strategies for optimizing the performance of hydraulic machines, ensuring that your operations not only meet but exceed industry standards. By implementing these best practices, businesses can enhance productivity, reduce downtime, and ultimately achieve higher profitability in an increasingly demanding environment.

Maximizing Performance: Understanding the Key Benefits of Hydraulic Machines in Industrial Applications

Hydraulic machines have become indispensable in various industrial applications, primarily due to their ability to enhance performance and efficiency. The integration of advanced hydraulic technology, such as positive flow electrohydraulic systems, significantly boosts the functionality of heavy machinery, leading to impressive operational outputs. For instance, the latest excavators feature larger boom cylinders that not only improve the lifting capacity but also ensure faster cycle times, thereby maximizing productivity on the job site.

Additionally, the selection of high-performance lubricants tailored for hydraulic systems is crucial in maintaining durability and efficiency. These biodegradable lubricants play a vital role in protecting equipment while aligning with sustainability goals, a growing trend within the industry. As companies increasingly focus on minimizing their environmental impact, understanding the interplay between hydraulic machine performance and sustainable practices becomes essential. Emphasizing energy-efficient designs and innovative technologies will propel industries toward a future where both performance and environmental responsibility coexist harmoniously.

Maximizing Efficiency in Hydraulic Machine Operations

Enhancing Operational Efficiency: The Role of Hydraulic Machines in Streamlining Production Processes

Hydraulic machines play a pivotal role in enhancing operational efficiency across various industries, particularly in manufacturing and construction. According to a report by the International Hydraulics Association, businesses that implement advanced hydraulic systems can increase productivity by up to 30%, primarily through improved automation and reduced labor costs. Hydraulic machines offer unparalleled power-to-weight ratios, making them ideal for heavy lifting and precise maneuvering. This increased efficiency translates into faster production times and the ability to handle larger workloads without compromising quality.

To maximize the benefits of hydraulic machines, consider these tips: ensure regular maintenance to prevent downtime; implementing hydraulic fluid management practices to prolong machine life and optimize performance; and invest in employee training to enhance the effective use of these systems, which can lead to a further 15% improvement in operational efficiency. Additionally, leveraging technology, such as IoT sensors, can provide real-time data on machine performance, allowing for predictive maintenance and more informed decision-making.

Another key strategy is to evaluate the hydraulic systems’ integration within your production line. A study from Machinery & Equipment Reports indicates that companies optimizing their hydraulic workflows saw a staggering 40% reduction in idle machine time. This not only improves overall efficiency but also decreases operational costs, allowing businesses to reinvest those savings into further innovation and growth. By streamlining these processes, companies can establish a more robust and agile production environment.

Cost-Effectiveness Analysis: How Investing in Hydraulic Machines Improves Bottom Lines

The integration of hydraulic machines across various industries is crucial for enhancing operational efficiency and solidifying a healthy bottom line. As analyzed in recent market reports, the hydraulic servo valve market is projected to grow significantly, reaching a size of approximately 2,144 million USD by 2032. This increase is driven primarily by the demand in key sectors such as aerospace, steel production, and energy, where precision and reliability are paramount.

Investing in advanced hydraulic systems, particularly nozzle throttling valves and jet valves, can yield considerable cost savings. For example, sectors like the petrochemical industry are increasingly adopting direct drive valves for their enhanced performance and energy efficiency, ultimately reducing operational costs. By transitioning to state-of-the-art hydraulic technologies, companies not only improve their product output but also minimize downtime, ensuring a stronger financial position in a competitive market landscape. This strategic investment exemplifies how hydraulic machines can act as a catalyst for cost-effectiveness and increased productivity, securing a company’s success in the evolving industrial environment.

Innovative Technologies: The Impact of Advanced Hydraulic Systems on Productivity Metrics

The integration of advanced hydraulic systems into various industries is revolutionizing productivity metrics. Innovative technologies such as robotics and artificial intelligence (AI) are playing a pivotal role in maximizing efficiency. For instance, in agricultural settings, AI-driven solutions can analyze data to enhance crop yields while minimizing losses. This approach not only improves operational efficiency but also helps growers make informed decisions in real-time.

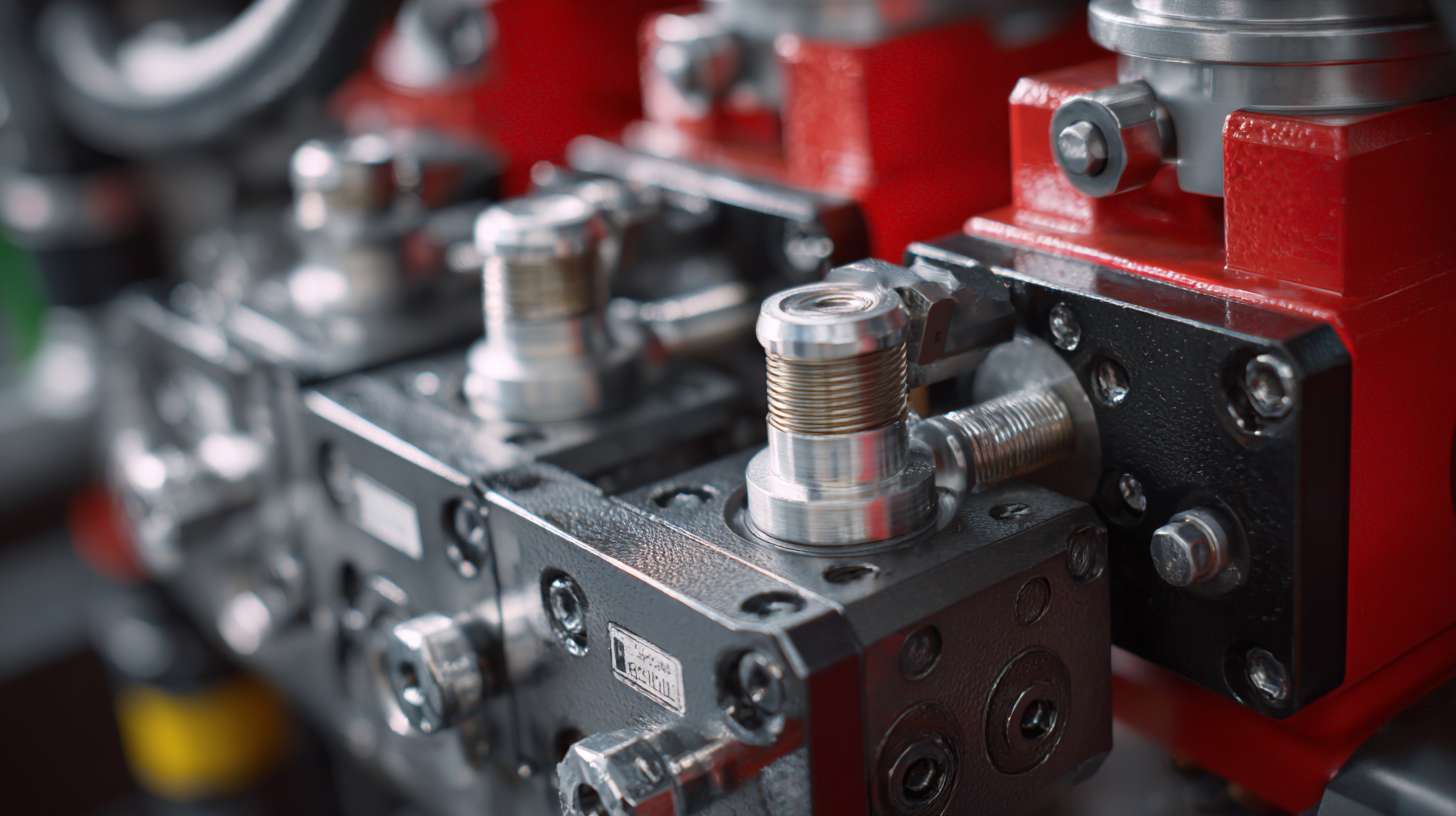

To leverage the benefits of advanced hydraulic systems, consider these tips: first, invest in sensors for hydraulic valve and system performance monitoring. These sensors can provide critical data insights, allowing for timely maintenance and optimizations. Second, explore digital twin technology to create virtual models of your hydraulic machinery. This can optimize operations, enhance fault detection, and improve overall resilience in your processes. Finally, staying updated with the latest market trends is essential. The hydraulics market is projected to witness substantial growth, so adopting cutting-edge technologies will keep your operations competitive and efficient.

Top Strategies for Maximizing Efficiency with the Best Hydraulic Machine in Your Industry - Innovative Technologies: The Impact of Advanced Hydraulic Systems on Productivity Metrics

| Hydraulic System Type | Efficiency Improvement (%) | Cost Reduction (%) | Productivity Increase (%) | Maintenance Frequency (per year) |

|---|---|---|---|---|

| Standard Hydraulic System | 10% | 5% | 8% | 2 |

| Electro-Hydraulic System | 15% | 7% | 12% | 1 |

| Smart Hydraulic System | 20% | 10% | 18% | 0.5 |

| Hybrid Hydraulic System | 18% | 8% | 15% | 1.5 |

Safety and Precision: How Modern Hydraulic Machines Reduce Risks and Improve Accuracy in Manufacturing

In the modern manufacturing landscape, safety and precision are paramount, and advanced hydraulic machines are leading the charge in enhancing these critical factors. According to a report by the International Society for Automation, nearly 70% of manufacturing incidents can be traced back to human error. However, the integration of automated hydraulic systems can significantly mitigate these risks. By utilizing precise controls and real-time monitoring, modern hydraulic machines minimize the likelihood of accidents and ensure higher operational accuracy.

To maximize the safety and efficiency of hydraulic machines, consider implementing regular maintenance schedules. Regularly inspecting hydraulic components and ensuring they are functioning within specified parameters can preemptively address potential failures and promote a safe working environment. Moreover, investing in operator training is essential; studies indicate that well-trained operators can reduce error rates by up to 30%, highlighting the importance of knowledge in operating complex machinery.

Additionally, leveraging technology such as predictive analytics can further enhance safety and precision. By analyzing data from machine operations, manufacturers can identify patterns that may indicate impending equipment failures. This proactive approach not only improves safety but also optimizes production efficiency, allowing companies to stay competitive in an ever-evolving market.