The Next Generation of Hydraulic Pump Motors Innovation and Impact

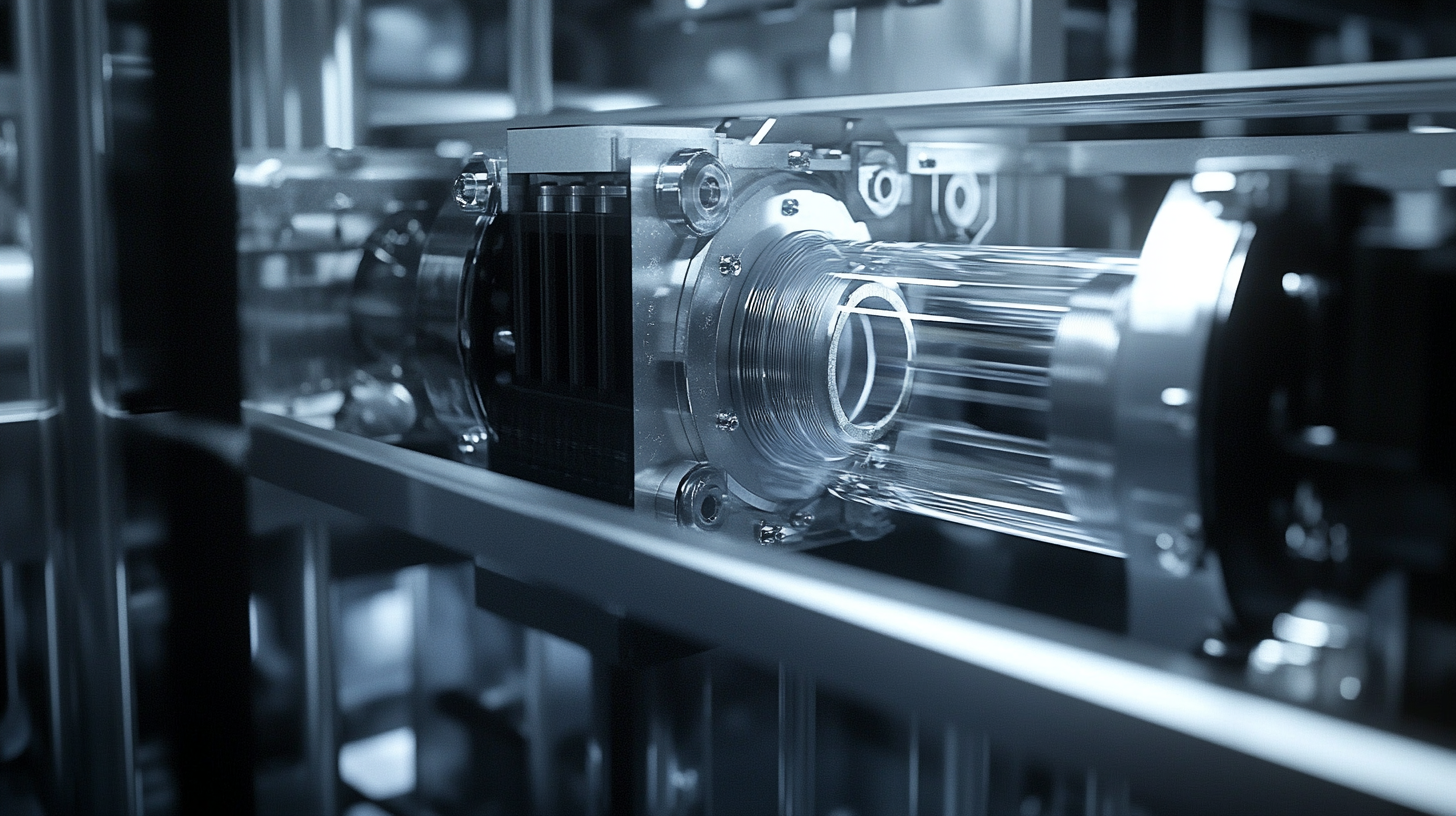

In the ever-evolving landscape of industrial machinery, hydraulic pump motors stand at the forefront of innovation, driving efficiency and performance across various applications. As industries demand more powerful, reliable, and versatile solutions, the next generation of hydraulic pump motors is set to revolutionize how we approach fluid power systems. These advancements promise not only improved functionality but also enhanced sustainability, addressing the pressing need for environmentally friendly technologies in an era that increasingly values eco-conscious practices.

The integration of cutting-edge technologies such as IoT connectivity, advanced materials, and smart control systems has paved the way for a new wave of hydraulic pump motors that deliver unprecedented levels of efficiency and adaptability. These innovations are not merely incremental improvements; they represent a fundamental shift in how hydraulic systems operate, with a significant impact on productivity and operational costs. As we delve into the future of hydraulic pump motors, it becomes evident that these developments will play a crucial role in transforming industries ranging from construction to manufacturing, ultimately shaping a greener and more efficient future.

Emerging Trends in Hydraulic Pump Motor Technology and Their Market Impact

The hydraulic pump motor technology landscape is undergoing a significant transformation, driven by emerging trends that promise to redefine performance and efficiency across various sectors. Recent analyses suggest a substantial market growth potential, with the global sanitary pumps and valves market projected to reach USD 3.1 billion by 2033, growing at a CAGR of 3.7%. This growth is largely fueled by innovative hydraulic solutions that integrate advanced materials and manufacturing techniques, such as metal 3D printing and novel control algorithms. As industries demand more from hydraulic systems, experts emphasize the importance of leveraging hydraulics expertise to improve electric machine designs. By combining traditional hydraulic principles with cutting-edge technologies, manufacturers can achieve enhanced performance attributes in their machinery. Furthermore, the integration of electrification and automation technologies will play a crucial role in modernizing hydraulic systems. Upcoming exhibitions, like bauma 2025, will showcase these innovations, positioning the industry at the forefront of technological advancement. Moreover, the introduction of products like the new electrohydraulic pump packages reflects a broader trend towards compact, efficient solutions tailored for hybrid applications. These advancements not only improve system efficiency but also reduce the overall footprint, making them suitable for a variety of modern machinery. As the hydraulic pump motor market continues to evolve, the synergy between innovation and practical applications will likely dictate the pace at which these technologies gain traction in the marketplace.

Key Innovations in Hydraulic Pump Motors and Their Efficiency Gains

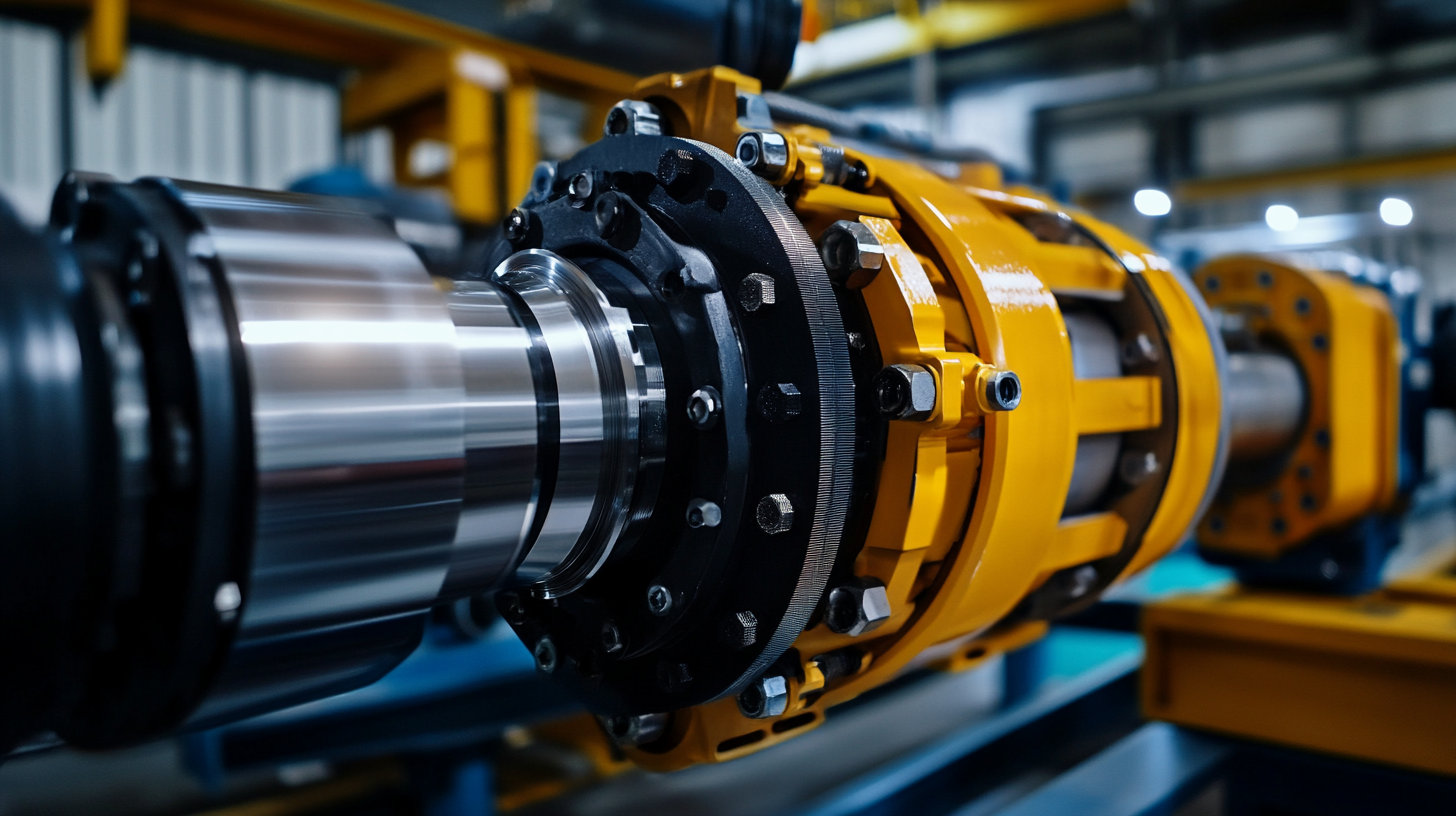

In the evolving landscape of hydraulic pump motors, recent innovations are paving the way for significant efficiency gains that resonate across various industries. The integration of advanced materials and cutting-edge manufacturing techniques is key to these developments. For instance, companies are increasingly adopting additive manufacturing technologies to create ultra-efficient hydraulic valves, which not only enhance performance but also reduce production waste. This shift is supported by industry research indicating that additive processes can lead to cost savings of up to 25% in production efficiency.

Furthermore, the introduction of hybrid permanent magnet motors represents another leap forward. These motors have been designed for electric submersible pump operations, showcasing a remarkable boost in performance due to their hybrid nature. Industry analysts report that such innovations can improve energy efficiency by more than 30%, translating into substantial operational cost savings for end-users.

In addition, exploring new materials like graphene holds the potential to revolutionize the performance of electric motors, including hydraulic systems. The addition of graphene to traditional copper wiring enhances electrical conductivity at high temperatures. According to studies, this innovation could yield an efficiency increase of approximately 15%, which is significant in a sector where every percentage point can lead to considerable energy savings.

Overall, the focus on efficiency and innovation in hydraulic pump motors reflects a broader trend toward sustainability and cost-effectiveness in industrial applications. The implications of these advancements will likely redefine operational standards and inspire further research and development in the field.

Analyzing the Role of Smart Technologies in Modern Hydraulic Systems

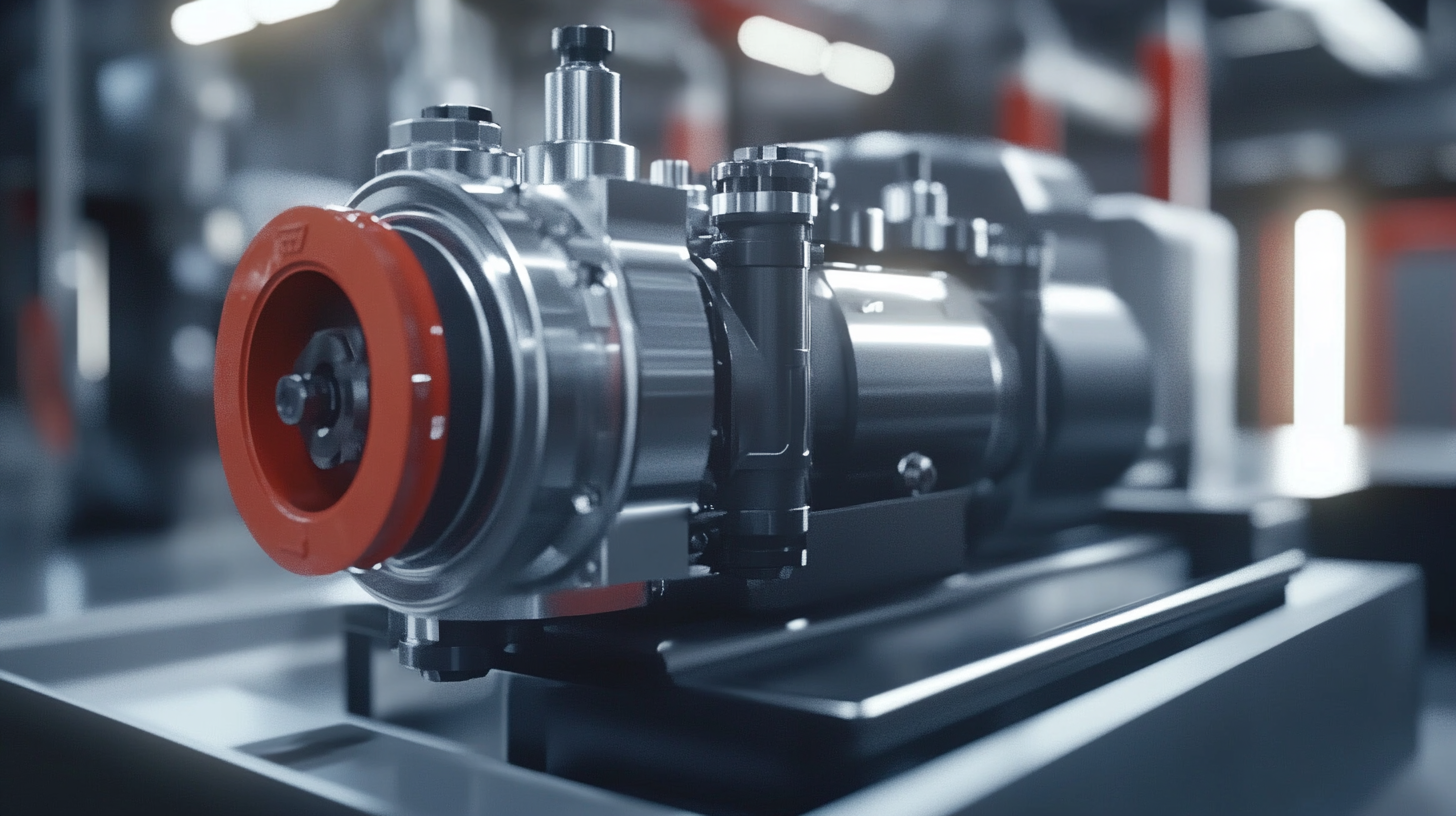

The integration of smart technologies into hydraulic systems marks a remarkable shift in the way mobile machinery operates. Modern hydraulic power units are now designed with greater intelligence and efficiency in mind, enabling mobile equipment to perform tasks that were previously thought to be unattainable. The inclusion of advanced sensors and predictive analytics allows for real-time monitoring and optimization of hydraulic performance, thereby improving overall machinery efficacy.

Moreover, the evolution of communication protocols within hydraulic systems signifies a broader industry trend toward digitization. The transition to more versatile protocols enhances the capability of hydraulic systems to communicate seamlessly with other technologies, facilitating smarter decision-making processes. This trend is particularly beneficial for mobile applications, where the need for responsive and adaptable hydraulic solutions is paramount.

As industries increasingly prioritize sustainability and efficiency, the modernization of hydraulic technologies becomes essential. Intelligent hydraulic systems not only contribute to enhanced performance but also reduce energy consumption, aligning with global goals for sustainable development. This convergence of smart technology and hydraulic design is set to redefine the landscape of mobile machinery, paving the way for innovations that will significantly influence future market trends.

Market Forecast: Growth Projections for Hydraulic Pump Motors by 2027

The global hydraulic pump motors market is poised for significant growth in the coming years. Projections indicate that by 2027, the market will witness substantial advancements fueled by technological innovations and increasing demand across various industries. As companies prioritize efficiency and performance in their operations, the need for advanced hydraulic systems becomes imperative. This drive towards modernization is expected to elevate the market size, aligning with broader trends observed in hydraulic equipment and machinery sectors.

Furthermore, environmental concerns and the push for sustainable solutions are likely to influence the hydraulic pump motors market dynamics. Innovations in design and performance—coupled with the integration of eco-friendly technologies—are set to redefine product offerings. Companies operating in this space must remain agile and responsive to these shifts, as the forecast suggests an estimated value increment that mirrors the rise in sustainable practices within the industrial landscape.

In addition to innovation, strategic collaborations and investment in research and development will be crucial for players aiming to capture market share. With a compound annual growth rate (CAGR) anticipated in the range of 3.9%, stakeholders can expect a competitive landscape that prioritizes cutting-edge solutions. The developing market trend indicates that the next generation of hydraulic pump motors will not only focus on operational efficiency but also emphasize durability and reduced environmental impacts, setting the stage for a revolutionary era in hydraulic technology.

Sustainability in Hydraulic Pump Motors: Innovations Reducing Environmental Impact

The importance of sustainability in modern engineering practices cannot be overstated, and hydraulic pump motors are no exception. As industries have become increasingly aware of their environmental footprints, the push towards greener technologies has sparked a wave of innovation in hydraulic pump motor design. These advancements are not only focused on enhancing efficiency but are also pioneering methods to significantly reduce energy consumption and harmful emissions, ensuring that the evolution of hydraulic systems aligns with global sustainability goals.

Innovative materials and cutting-edge designs are at the forefront of this change. Manufacturers are now utilizing lightweight, durable composites that minimize weight without sacrificing performance. These materials not only lead to more efficient operation by reducing energy requirements but also enhance the overall lifespan of the motors, which contributes to reduced waste. Additionally, advancements in smart technology integration allow for real-time monitoring and optimization of hydraulic systems, further improving their environmental performance by adjusting operations to minimize power use during less intensive tasks.

Moreover, the advent of bio-based lubricants and more efficient hydraulic fluids represents a significant leap towards sustainability. These environmentally friendly alternatives reduce the risk of pollution and are designed to break down more readily than traditional oils, further mitigating the environmental impact. By shifting towards these innovative solutions, the hydraulic pump motor industry is proving that economic performance and environmental responsibility can go hand in hand, paving the way for a sustainable future in industrial applications.