Exploring the Top Examples of Best Hydraulic Motors for Global Buyers

As industries continue to evolve in the face of technological advancements, hydraulic motors have emerged as a backbone for various applications, significantly enhancing operational efficiency and productivity. According to a recent market analysis by Research and Markets, the global hydraulic motors market is projected to reach approximately USD 7 billion by 2025, growing at a CAGR of around 5% from 2020 to 2025. This growth is fueled by increasing demand from sectors such as construction, agriculture, and manufacturing, where hydraulic motors provide superior torque and precise motion control. Furthermore, innovations in hydraulic motor technology, including the development of compact designs and alternative energy sources, are set to redefine industry standards.

In this blog, we will explore the top examples of hydraulic motors, examining their design features, performance metrics, and the transformative trends shaping the market landscape for global buyers.

Understanding Hydraulic Motors: Types and Applications

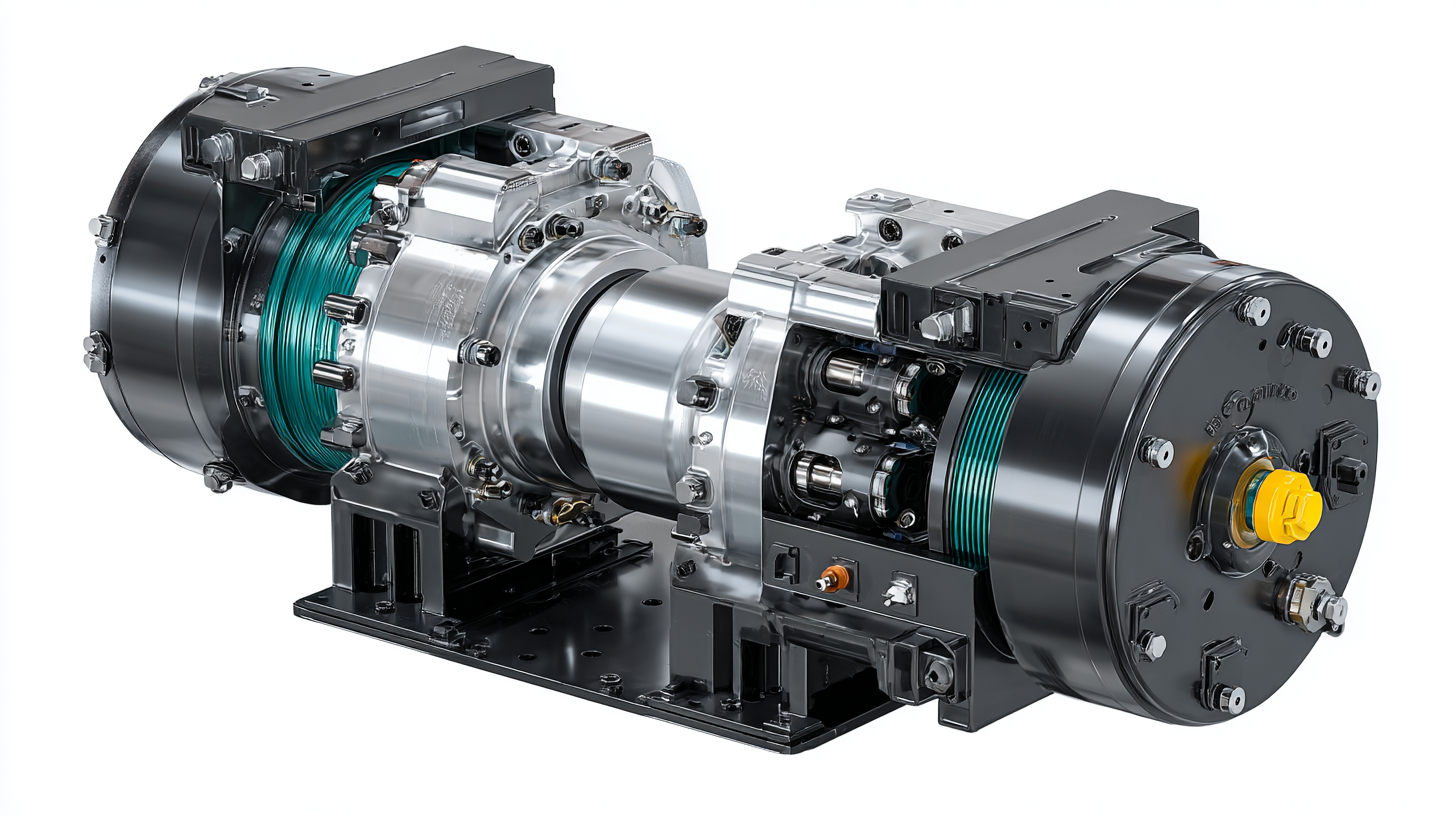

Hydraulic motors play a crucial role in various industrial applications, and their understanding is vital for global buyers. There are several types of hydraulic motors, including gear motors, vane motors, and piston motors, each offering unique advantages depending on the application. Gear motors are known for their simplicity and robustness, making them ideal for systems requiring high torque at lower speeds. In contrast, vane motors excel in applications where smooth operation and lower noise levels are required, while piston motors are preferred in high-efficiency systems due to their ability to handle high pressures and provide variable output.

Applications of hydraulic motors span across multiple industries. In manufacturing, they are used in machinery for automation, enhancing productivity and efficiency. In the construction sector, hydraulic motors power heavy equipment such as excavators and loaders, enabling them to perform various tasks with precision. Moreover, in the automotive industry, these motors facilitate operations like power windows and seat adjustments, improving user experience. Understanding the diverse types and their specific applications allows global buyers to make informed decisions when selecting hydraulic motors for their needs.

Key Features to Look for in High-Quality Hydraulic Motors

When selecting high-quality hydraulic motors, it is crucial to focus on several key features that ensure reliability and efficiency. Firstly, the motor's displacement is a critical factor; it should ideally range between 10 to 200 cc/rev for most applications, as per the 2023 Hydraulic Motor Market Analysis report. A higher displacement provides greater torque, which is essential for demanding tasks such as excavation or material handling. Additionally, look for motors with a robust design that can withstand high pressures, typically around 3000 psi or more, in industrial environments.

Another vital aspect to consider is the efficiency rating of the motor. According to a recent study from the International Journal of Fluid Power, high-quality hydraulic motors boast efficiency rates exceeding 85%. This means less energy wastage, translating to cost savings over time in operational settings. Also, consider the type of hydraulic motor: gear, vane, or piston, each offering distinct operational benefits. Gear motors, for instance, are known for their simplicity and durability, while piston motors provide higher efficiency at varying loads.

**Tips:** Always check for warranty and service support when investing in hydraulic motors. A good warranty can indicate the manufacturer’s confidence in their product. Additionally, seek out motors with easy maintenance features, as these can significantly reduce downtime and maintenance costs in the long run.

Top Brands and Models of Hydraulic Motors for Global Markets

When it comes to hydraulic motors, global buyers are often looking for reliability, efficiency, and performance. Some of the top brands that stand out in the marketplace include Bosch Rexroth, Eaton, and Parker Hannifin. Each of these manufacturers offers a diverse range of hydraulic motors suited for various applications, from mobile machinery to industrial equipment. Bosch Rexroth is known for their innovative technologies that enhance energy efficiency, while Eaton’s motors are celebrated for their robust design. On the other hand, Parker Hannifin provides a wide selection of hydraulic components, solidifying their reputation in diverse sectors.

When choosing a hydraulic motor, it's essential to consider your specific application needs. **Tip 1:** Evaluate the motor's torque characteristics and speed ranges to ensure they align with your operational requirements. Additionally, **Tip 2:** pay attention to the motor's compatibility with other hydraulic components in your system, as this can affect overall performance. Lastly, **Tip 3:** prioritize brands with a strong service network, providing accessible support and parts to minimize downtime in your operations. These considerations will help you select the best hydraulic motor for your application and ensure long-term reliability and performance.

Comparative Analysis: Performance Metrics of Leading Hydraulic Motors

In the competitive landscape of hydraulic motors, performance metrics are pivotal in guiding global buyers towards the best options. Key parameters such as torque, efficiency, and operational lifespan distinguish leading hydraulic motors. For instance, according to the "Hydraulic Motor Market Analysis 2023" report by Market Research Future, high-efficiency hydraulic motors, particularly axial piston motors, can achieve peak efficiencies of up to 92% under optimal conditions. This attribute not only maximizes performance but also translates to significant energy savings over the lifespan of the equipment.

Additionally, the comparative analysis of hydraulic motor performance reveals that gear motors often provide superior torque output, making them ideal for applications demanding high starting torque. The same report indicates that gear motors can produce torque ratings exceeding 500 Nm, while also maintaining a compact design. This versatility positions them favorably for industries ranging from construction to manufacturing, where space constraints and power requirements are critical. Understanding these performance metrics allows global buyers to make informed decisions and invest in hydraulic motors that align with their operational needs.

Maintenance Tips to Extend the Lifespan of Hydraulic Motors

Maintaining hydraulic motors is crucial for ensuring their longevity and optimal performance in various applications, from construction machinery to agricultural equipment. According to a report by the International Fluid Power Society, regular maintenance can increase the lifespan of hydraulic motors by up to 30%. This statistic underscores the importance of routine checks to detect leaks, monitor fluid levels, and replace worn components before they lead to more significant issues.

Key maintenance practices include ensuring proper hydraulic fluid is used, as many industrial applications recommend specific viscosity grades that can significantly affect performance. The National Fluid Power Association also highlights that contamination is a leading cause of hydraulic system failure, accounting for approximately 70% of breakdowns. Implementing stringent filtration systems and regularly changing the hydraulic fluid can mitigate this risk, ultimately extending the life of hydraulic motors.

Regular inspections and preventive maintenance can save operators unnecessary downtime and repair costs, making them a worthy investment for any business relying on hydraulic systems.