Troubleshooting Common Issues in Hydraulic Parts: A Global Procurement Perspective

In the rapidly evolving landscape of manufacturing and construction, hydraulic parts play a pivotal role in ensuring operational efficiency and reliability. According to the International Fluid Power Association (IFPA), the global hydraulic components market is projected to reach USD 57 billion by 2026, reflecting the growing demand for advanced hydraulic systems. However, as with any complex machinery, these components are susceptible to a range of issues that can hinder performance and productivity. This blog aims to provide a comprehensive troubleshooting checklist for common hydraulic parts issues, tailored for procurement professionals navigating a global marketplace. By understanding the typical challenges and their solutions, stakeholders can better mitigate risks, enhance system longevity, and ensure optimal functionality in their hydraulic applications.

Hydraulic System Component Failures: Analyzing the Statistics and Causes

Hydraulic systems are critical in various industries, providing power and efficiency in heavy machinery and equipment. However, the reliability of these systems often hinges on the performance of individual components. Statistical analyses reveal that component failures are frequent, with seals, pumps, and hoses accounting for a significant percentage of reported issues. By examining the root causes of these failures, we can implement measures to mitigate risks and enhance system longevity.

For instance, improper installation and maintenance can lead to premature wear and tear of hydraulic components. Statistics indicate that a large number of failures stem from inadequate training of personnel responsible for system upkeep. Additionally, external factors such as operating conditions and environmental stressors can exacerbate component degradation. Understanding these underlying causes equips procurement specialists with the knowledge needed to source higher-quality parts and establish better maintenance protocols, ultimately reducing downtimes and repair costs for hydraulic systems worldwide.

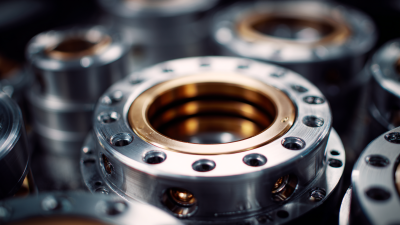

The Impact of Material Quality on Hydraulic Part Performance: A Global Review

The quality of materials used in hydraulic parts is paramount to their performance and longevity in various applications. When it comes to hydraulic systems, even minor deficiencies in material quality can lead to significant operational issues, including leaks and reduced efficiency. An investigation into the global procurement landscape reveals that sourcing from reputable suppliers who prioritize high-grade materials can drastically mitigate these risks. By ensuring that the materials comply with international standards, manufacturers can enhance the reliability and durability of hydraulic components.

Additionally, the impact of material quality extends beyond mere performance metrics; it directly influences maintenance costs and system downtime. Many companies are revisiting their procurement strategies to emphasize quality over cost. The integration of advanced materials, such as high-strength alloys and innovative composites, is becoming more common as organizations strive to optimize their hydraulic systems. Investing in superior materials not only improves functionality but also offers long-term savings by reducing maintenance frequency and enhancing overall system efficiency.

This global review highlights the necessity for stakeholders to prioritize material quality in their hydraulic part procurement processes to ensure operational excellence.

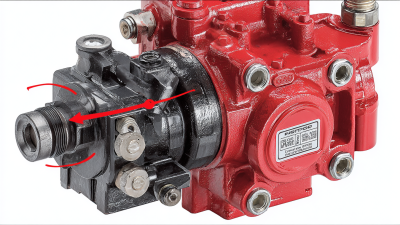

Top 5 Common Hydraulic Parts Issues: Frequency and Their Solutions

When it comes to hydraulic systems, certain issues frequently arise that can interrupt operations and lead to costly downtime. Understanding these common problems is essential for anyone involved in global procurement of hydraulic parts. One major issue is leakages in hydraulic hoses and fittings, which may result from wear and tear or improper installation. Regular inspection and using high-quality components can mitigate this issue, ensuring a longer lifespan for the system.

Another prevalent problem is overheating of hydraulic fluids, often caused by excessive load or inadequate cooling. This not only affects efficiency but can also lead to system failure. Implementing proper load management and routine maintenance checks can help identify potential overheating situations early. Lastly, contamination of the hydraulic fluid is a critical challenge faced globally. Employing filtration systems and regular fluid analysis can significantly reduce the risk of damage from contaminants, keeping the hydraulic system performing optimally. Addressing these common issues proactively can lead to improved efficiency and cost savings across hydraulic operations.

Troubleshooting Common Issues in Hydraulic Parts: A Global Procurement Perspective

| Issue | Frequency (%) | Possible Causes | Solutions |

|---|---|---|---|

| Oil Leakage | 30% | Worn seals, improper connections, damage | Inspect seals, replace as necessary, ensure tight connections |

| Unusual Noise | 25% | Cavitation, air in the system, or worn parts | Bleed the system, check for air leaks, inspect for worn components |

| Slow Actuation | 20% | Blockages, low fluid levels, faulty valves | Check fluid levels, clean filters, inspect and replace valves |

| Overheating | 15% | Low fluid levels, coolant issues, excessive load | Ensure adequate fluid levels, check and repair cooling systems |

| Valve Failure | 10% | Dirt buildup, wear and tear, incorrect adjustment | Regular maintenance, clean and adjust valves as necessary |

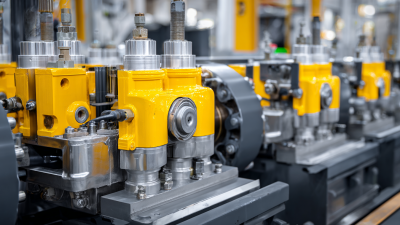

Best Practices for Sourcing Reliable Hydraulic Components in a Competitive Market

Sourcing reliable hydraulic components in a competitive market requires a strategic approach that takes into account both quality and cost-effectiveness. As supply chains evolve, businesses must leverage procurement intelligence to navigate challenges, ensuring access to superior materials. The Polyvinyl Chloride (PVC) market exemplifies this trend, with projections indicating a steady rise in demand due to its cost benefits and recyclability. Companies focusing on these factors are better positioned to optimize their hydraulic part procurement processes.

**Tip 1:** Conduct thorough research on suppliers to assess their reliability and performance metrics. Utilize industry reports that offer insights into supplier capabilities and market trends, as these can provide crucial information for making informed decisions.

**Tip 2:** Incorporate sustainability into your procurement strategies. By prioritizing suppliers who offer environmentally friendly components, businesses can enhance their brand reputation while meeting regulatory requirements. Industry data shows that sustainable sourcing is increasingly preferred, impacting customer choice and loyalty positively.

A proactive approach to sourcing, supported by data-driven insights, will ensure that manufacturers secure dependable hydraulic parts while maintaining a competitive edge in the marketplace.

Troubleshooting Common Issues in Hydraulic Parts

This chart illustrates the sourcing challenges faced in the procurement of hydraulic components based on data collected from various industries. The data is segmented into four key issues encountered during sourcing: Quality Assurance, Delivery Delays, Cost Management, and Compatibility Issues.

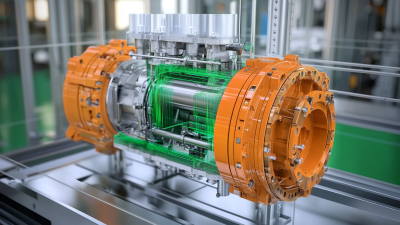

Leveraging Data Analytics to Predict and Prevent Hydraulic System Failures

In the rapidly evolving landscape of hydraulic systems, leveraging data analytics is becoming essential for predicting and preventing potential failures. By harnessing large datasets generated from hydraulic parts and systems, organizations can identify patterns and trends that may indicate an impending issue. Advanced analytics tools enable the processing of real-time data to monitor system performance continuously, making it possible to detect anomalies before they lead to significant breakdowns. This proactive approach to maintenance not only enhances system reliability but also reduces downtime, ultimately leading to cost savings.

Moreover, the integration of predictive analytics into procurement strategies can significantly improve decision-making processes. By analyzing historical performance data alongside current market trends, companies can forecast the demand for specific hydraulic components and optimize inventory levels. This ensures that critical parts are readily available when needed, minimizing disruptions caused by supply chain delays.

As data analytics tools become more sophisticated, their application in the hydraulic sector will empower businesses with the insights necessary to maintain operational efficiency, safeguard equipment longevity, and improve overall production outcomes.

Related Posts

-

China's Smart Manufacturing Leading Global Sales of Quality Hydraulic Parts

-

Navigating the Global Market for Best Hydraulic Parts with Crucial Import Export Certifications

-

How to Maximize Cost Efficiency with Top-tier After-sales Support for Your Best Tractor Hydraulic Pump

-

Mastering Hydraulic Pumps: A Step-by-Step Guide for Global Buyers

-

2025 Innovations in Hydraulic Pumps: Transforming Efficiency and Sustainability in Industrial Applications

-

Maximizing Efficiency: The Unmatched Benefits of Best Pumps and Motors for Global Supply Chains