Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types

In recent years, the demand for efficient and reliable Hyd Pumps has surged, driven by the relentless pursuit of energy efficiency and cost-effectiveness across various industrial sectors. According to a report by the International Energy Agency (IEA), the global market for hydraulic pumps is projected to reach USD 11 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.7%. As industries increasingly turn to advanced hydraulic systems for improved operational performance, understanding the unique features and applications of the best Hyd Pumps becomes essential. This blog will not only explore these attributes but also provide guidance on how to find quality suppliers that can meet the diverse needs of modern applications, ensuring that businesses can leverage the full potential of hydraulic technology.

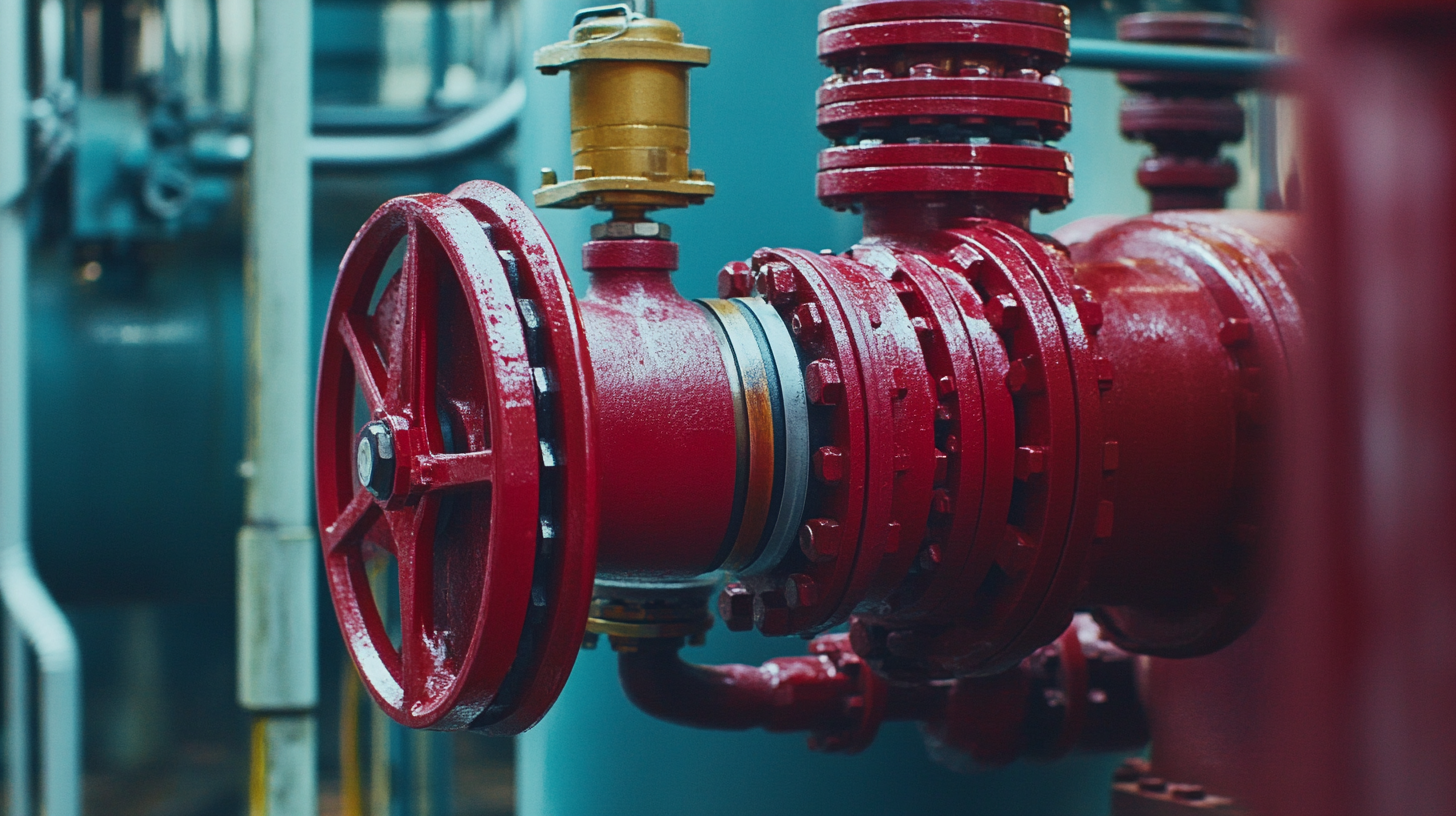

Understanding Hydraulic Pump Basics: Types and Functions

Hydraulic pumps play a crucial role in various industrial applications, serving as the vital link that transfers hydraulic energy. Understanding the basic types and functions of hydraulic pumps is essential for maximizing efficiency in setup and maintenance. The most common types include gear pumps, piston pumps, and vane pumps, each serving distinct purposes. Gear pumps are renowned for their simplicity and durability, making them ideal for low-viscosity fluids. Piston pumps, on the other hand, are known for their high pressure and efficiency over a broad range of speeds, while vane pumps offer a balance of flow and pressure output, suitable for diverse applications.

**Tips:** When selecting a hydraulic pump, consider the required pressure and flow rate of your system. Overestimating these specifications can lead to increased energy consumption and potential damage. It's also important to regularly maintain your pumps to avoid unexpected failures. Regular oil changes and monitoring for leaks can significantly extend the lifespan of your equipment.

In addition to understanding pump types, it's vital to recognize their applications. For instance, gear pumps are often used in transmitting fluids in automotive applications, whereas piston pumps are frequently found in construction equipment due to their power efficiency. By choosing the right type of pump for your specific application, you can enhance performance and minimize operational costs.

**Tips:** Conduct a thorough analysis of the environment where the pump will operate. Factors such as temperature, viscosity, and potential contaminants can influence your pump's performance and reliability. Always consult with professionals when uncertain, as expert advice can be invaluable in optimizing your hydraulic system.

Exploring the Unique Features and Applications of the Best Hyd Pumps

| Pump Type | Functionality | Typical Applications | Efficiency |

|---|---|---|---|

| Gear Pump | Positive displacement using gears | Hydraulic drives, automotive applications | High efficiency at steady flow |

| Vane Pump | Uses sliding vanes to pump fluid | Construction, material handling | Moderate efficiency, good for variable flow |

| Piston Pump | Uses pistons to move fluid | High-pressure applications, industrial systems | High efficiency, capable of high pressures |

| Diaphragm Pump | Uses a flexible diaphragm | Chemical transfer, food processing | Good for corrosive fluids, moderate efficiency |

| Screw Pump | Progressive cavity principle | Oil and gas, waste treatment | Consistent flow rate, high efficiency |

Comparative Analysis: Common Hydraulic Pumps Versus Alternatives

The comparative analysis of hydraulic pumps is pivotal to understanding their efficiency and application in various fields. Traditional hydraulic pumps, such as gear pumps and piston pumps, dominate the market due to their reliability and established technology. However, alternative types like brushless DC and switched reluctance motors are gaining attention, particularly in off-grid water pumping systems (OGWPS). Research shows that brushless DC motors can enhance efficiency by up to 30% compared to conventional counterparts, while switched reluctance motors provide notable advantages in durability and maintenance, crucial for remote locations.

Moreover, studies on pump as turbines (PAT) have highlighted significant performance enhancements through impeller modification techniques. Computational fluid dynamics (CFD) software, such as Ansys CFX, reveals that optimized impeller designs can lead to performance gains of 15-25%. Additionally, integrating a hydraulic energy regeneration unit (HERU) with pilot relief valves can effectively minimize energy losses, especially under high-pressure conditions. These innovations emphasize the need for ongoing research and development to refine the capabilities of both traditional and alternative hydraulic pump technologies in achieving sustainable energy solutions.

Innovative Applications: Where Unique Hydraulic Pumps Excel

Hydraulic pumps play a crucial role in various industrial applications, providing power and efficiency in a wide range of sectors. Among the unique features of innovative hydraulic pumps, their ability to handle varying pressures and fluid types stands out. For instance, variable displacement pumps have gained popularity for their energy efficiency and precision in fluid management, as reported in the latest industry analysis. These pumps can adapt to different operational needs, reducing energy consumption by up to 30% compared to fixed displacement counterparts.

Moreover, alternative hydraulic pumps, such as gear and diaphragm pumps, showcase exceptional capabilities in specific applications. Diaphragm pumps, known for their ability to handle corrosive fluids, are increasingly utilized in chemical processing industries. According to recent industry statistics, the global diaphragm pump market is projected to grow at a CAGR of over 6% from 2023 to 2030, underlining their rising demand. In addition, gear pumps are being favored for their compact design and high reliability, making them ideal for automotive and manufacturing applications. As innovation in hydraulic pump technology continues to advance, these unique features and applications will increasingly shape the landscape of hydraulic systems across various industries.

Maintenance Tips: Ensuring Longevity for Various Hydraulic Pump Types

Maintaining hydraulic pumps is essential for ensuring their longevity and optimal performance across various applications. As the hydraulics market is projected to grow from $39.40 billion in 2025 to $44.26 billion by 2030, the importance of proper maintenance practices cannot be overstated. Regular preventative and predictive maintenance strategies can significantly enhance the lifespan of hydraulic systems. This involves frequent inspections, oil and filter changes, and timely repairs, which are critical to maintaining hydraulic integrity and efficiency.

For example, many advanced hydraulic systems, such as those found in modern tractors, utilize separate oils and filters for various components, which allows for targeted maintenance and improved reliability. These practices not only reduce the risk of unexpected breakdowns but also maximize the performance of hydraulic applications.

Incorporating high-quality biodegradable lubricants in these systems can further extend equipment life, aligning with the industry's move towards sustainability in hydraulic design and maintenance. By prioritizing maintenance, operators can ensure that their hydraulic pumps remain effective and reduce the total cost of ownership in the long term.

Future Trends: Advancements in Hydraulic Pump Technology and Design

The rapid evolution of hydraulic pump technology is paving the way for enhanced efficiency and versatility in numerous applications. Advancements in materials science have led to the development of lighter and more durable pumps that can withstand extreme conditions. These innovations not only improve the performance of hydraulic systems but also reduce energy consumption, making operations more sustainable. For instance, the integration of smart sensors within pumps allows for real-time monitoring and predictive maintenance, thereby minimizing downtime and operational costs.

Furthermore, the trend towards automation and IoT (Internet of Things) integration has transformed how hydraulic systems are managed. Future hydraulic pumps are increasingly being designed with connectivity in mind, enabling seamless communication with other machinery and systems. This transformation is relevant across various industries, from manufacturing to renewable energy, where precise control and efficiency are crucial. As hydraulic pump technology continues to advance, we can expect to see even more innovative designs and applications that will redefine traditional practices and enhance productivity.