What Makes a Mixer Pump Essential for Modern Industry

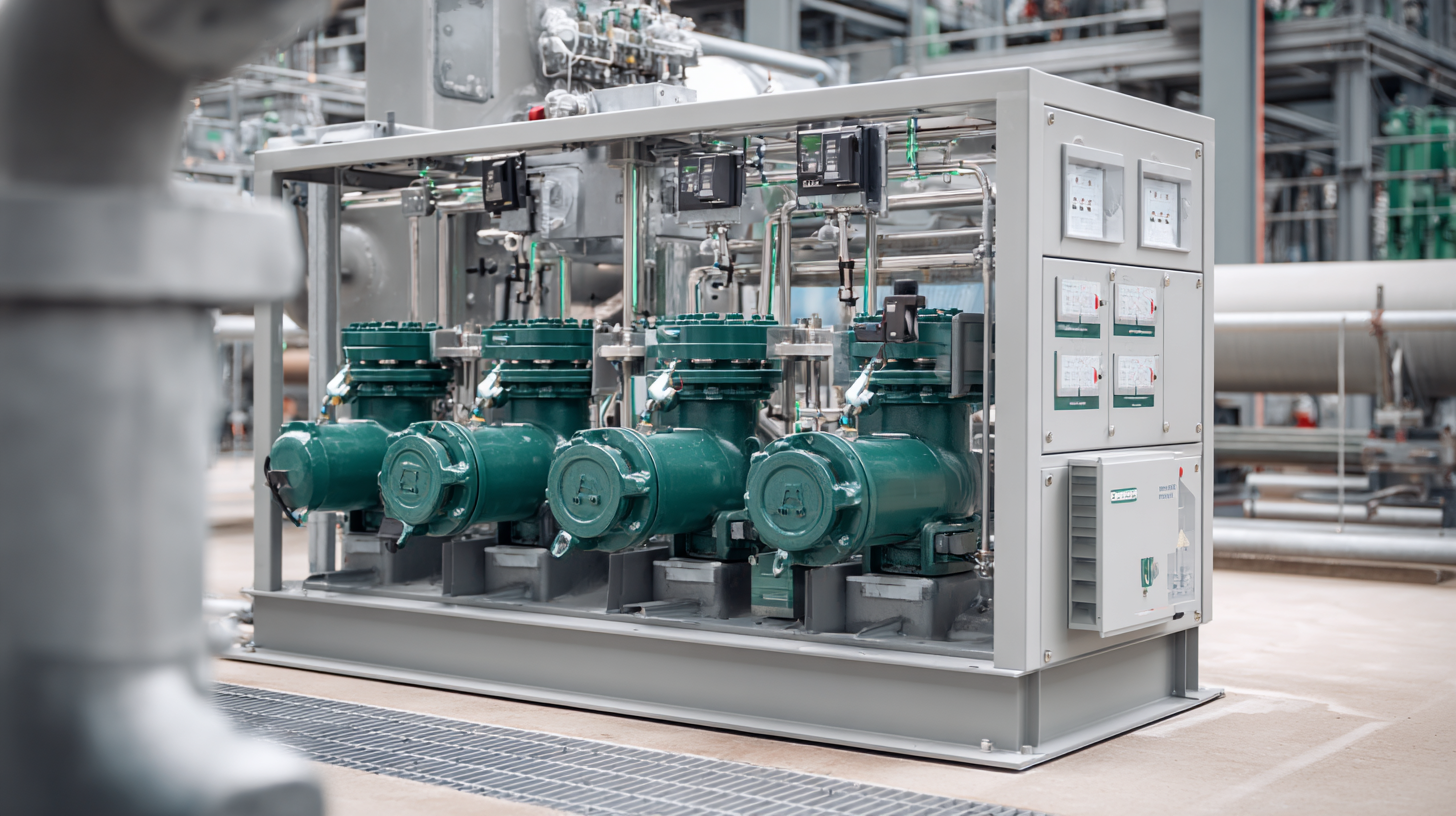

In today's rapidly evolving industrial landscape, efficiency and versatility are paramount, making the Mixer Pump an indispensable tool across various sectors. This innovative equipment not only enhances the mixing and pumping capabilities of liquids but also streamlines production processes by ensuring consistent quality and uniformity in formulations.

The integration of digital technology into Mixer Pumps has further revolutionized operations, enabling real-time monitoring and control, which significantly optimizes workflow and reduces downtime. As industries increasingly depend on automation and precise handling of materials, understanding the essential features and advantages of Mixer Pumps becomes crucial.

The integration of digital technology into Mixer Pumps has further revolutionized operations, enabling real-time monitoring and control, which significantly optimizes workflow and reduces downtime. As industries increasingly depend on automation and precise handling of materials, understanding the essential features and advantages of Mixer Pumps becomes crucial.

This article will explore the pivotal role of Mixer Pumps in modern industry, highlighting their benefits, applications, and the technological advancements that are shaping their future.

Key Features of Mixer Pumps That Enhance Industrial Efficiency

Mixer pumps play a pivotal role in modern industrial processes by providing efficient mixing and pumping solutions. One of their key features is the ability to maintain a consistent flow rate while mixing various materials. This ensures that products meet strict quality standards and reduces the risk of inconsistencies during production. Moreover, mixer pumps are designed to handle a wide range of materials, from viscous liquids to powders, making them versatile tools for different industries, including construction, pharmaceuticals, and food processing.

Mixer pumps play a pivotal role in modern industrial processes by providing efficient mixing and pumping solutions. One of their key features is the ability to maintain a consistent flow rate while mixing various materials. This ensures that products meet strict quality standards and reduces the risk of inconsistencies during production. Moreover, mixer pumps are designed to handle a wide range of materials, from viscous liquids to powders, making them versatile tools for different industries, including construction, pharmaceuticals, and food processing.

Tips: When selecting a mixer pump, consider the material viscosity and the nature of the substances being mixed. This will help you choose a pump with suitable power and mixing capabilities for your specific needs. Regular maintenance and monitoring can also prevent downtime and ensure the pump operates at peak efficiency.

Another significant benefit of mixer pumps is their ability to integrate with automated systems, enhancing industrial efficiency. This automation allows for precise control over the mixing process, reducing human error and minimizing waste. Additionally, modern mixer pumps often incorporate energy-efficient designs, which can lead to significant cost savings over time.

Tips: Invest in a mixer pump that offers real-time monitoring and data analytics features to optimize performance and identify potential issues before they escalate.

The Role of Mixer Pumps in Streamlining Production Processes

Mixer pumps play a pivotal role in modern industries by enhancing production processes across various sectors. These sophisticated machines streamline the mixing and pumping of materials, ensuring consistency and efficiency in operations. For instance, recent reports indicate that the adoption of advanced mixing technologies can lead to up to 30% improvement in production output. This is particularly crucial in industries like animal feed production, where consistent ingredient blending directly affects product quality. Companies achieving record production levels, such as those in Western Australia, have attributed their success to the integration of modern mixer pumps that optimize their operational workflows.

Furthermore, the efficiency gains provided by mixer pumps contribute significantly to energy savings. Research shows that facilities that implement high-efficiency mixer pumps can decrease energy consumption by nearly 20%, leading to substantial cost reductions over time. The ongoing national projects, such as those in the secondary battery sector, highlight the demand for innovative mixing solutions that not only enhance productivity but also align with sustainability goals. By leveraging these advanced technologies, manufacturers are able to navigate the challenges of scaling operations while maintaining stringent quality standards and reducing environmental impact.

Safety Benefits of Using Mixer Pumps in Modern Manufacturing

In modern manufacturing, the use of mixer pumps has revolutionized various processes, particularly in enhancing safety protocols. One of the primary benefits of mixer pumps is their ability to efficiently blend and transport viscous materials, reducing the need for manual handling. This automation minimizes the risk of accidents associated with manual mixing, such as spills and exposure to hazardous chemicals. By incorporating these pumps, industries can significantly lower the likelihood of injuries, ensuring a safer working environment.

Additionally, mixer pumps are designed with advanced safety features that protect operators from potential hazards. Many models include automatic shut-off systems and pressure relief valves, which prevent over-pressurization and equipment failures. This proactive safety mechanism not only safeguards equipment but also enhances the overall operational efficiency of manufacturing processes. With a focus on both productivity and safety, mixer pumps have become indispensable tools in modern industry, aligning technological advancement with the imperative of worker well-being.

Cost-Effectiveness: How Mixer Pumps Save Resources in Industry

In today's rapidly evolving industrial landscape, mixer pumps have become indispensable due to their cost-effectiveness. According to a recent industry report by Global Market Insights, mixer pumps can reduce operational costs by up to 30% through enhanced efficiency in mixing and pumping processes. This significant reduction in costs not only helps companies allocate resources more effectively but also leads to increased profitability. By ensuring optimal mixing of materials, these pumps minimize waste, thereby saving both time and raw materials essential in production.

Tips: Regular maintenance of mixer pumps can further enhance their efficiency. Ensure that you schedule routine inspections to identify any potential issues before they escalate.

Moreover, companies utilizing mixer pumps are able to achieve faster project turnaround times, which can lead to more contracts and heightened competitiveness in the market. A study by the American Society of Mechanical Engineers highlighted that industries employing advanced mixing solutions reported a productivity boost of 20%. This improvement in efficiency illustrates how mixer pumps are not merely a cost-saving device but a strategic investment that modern enterprises can leverage for sustainable growth.

Tips: Invest in operator training programs; well-trained personnel can significantly maximize the efficiency of mixer pump operations.

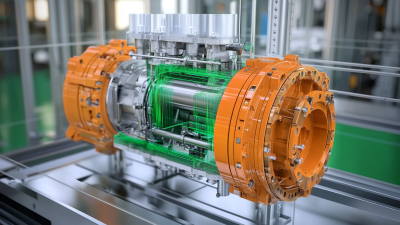

Innovative Technologies in Mixer Pumps for Enhanced Performance

In today's fast-paced industrial landscape, mixer pumps are vital for streamlining processes and ensuring optimal efficiency. The integration of innovative technologies in mixer pumps has significantly enhanced their performance, allowing industries to meet rising demands with exceptional precision. Advanced features such as smart automation, real-time monitoring, and energy-efficient designs have emerged as game-changers. According to a report by MarketsandMarkets, the global mixer pump market is projected to reach USD 6.9 billion by 2025, driven by key advancements in technology and a growing focus on sustainability.

One major innovation is the incorporation of IoT (Internet of Things) capabilities, enabling operators to remotely monitor and control mixer pumps with ease. This connectivity minimizes downtime and allows for predictive maintenance, which can reduce operational costs by up to 25%, based on findings from a study by Frost & Sullivan. Furthermore, the development of advanced materials has enhanced the durability and reliability of these pumps, leading to longer lifespans and reduced maintenance frequencies.

**Tips:** To maximize the benefits of modern mixer pumps, consider implementing regular training for your staff on the latest technologies. Additionally, maintain an up-to-date inventory of spare parts to minimize downtime during maintenance. Embracing these innovative solutions will not only enhance your operational efficiency but also keep you competitive in a rapidly evolving market.

Performance Metrics of Mixer Pumps in Modern Industry

Related Posts

-

Innovative Pump Technology Leading Global Market Trends in Efficiency and Sustainability

-

The Next Generation of Hydraulic Pump Motors Innovation and Impact

-

Top 10 Tyrone Hydraulic Pump Manufacturers from China at the 137th Canton Fair

-

How to Choose the Best Pump Parts for Optimal Efficiency and Longevity in Your Operations

-

Mastering Eaton Hydraulic Motors A Comprehensive Guide for Beginners

-

2025 Innovations in Hydraulic Pumps: Transforming Efficiency and Sustainability in Industrial Applications