Mastering Eaton Hydraulic Motors A Comprehensive Guide for Beginners

In the ever-evolving landscape of hydraulic technology, Eaton Hydraulic Motors stand out as a leading choice among professionals for their reliability and efficiency. According to recent industry reports, the hydraulic motors market is projected to reach approximately $8.5 billion by 2026, with Eaton playing a pivotal role in this growth. As industries increasingly seek to optimize performance and reduce costs, understanding the alternative types of hydraulic motors becomes essential for both new enthusiasts and seasoned engineers. This comprehensive guide aims to illuminate the various options available, highlighting the unique attributes of Eaton Hydraulic Motors, and providing insights into how these alternatives can be effectively employed in diverse applications. Whether you're exploring replacement options or seeking to enhance your systems, mastering the nuances of hydraulic motors is crucial for maximizing efficiency and productivity.

Understanding the Basics of Eaton Hydraulic Motors: Components and Functionality

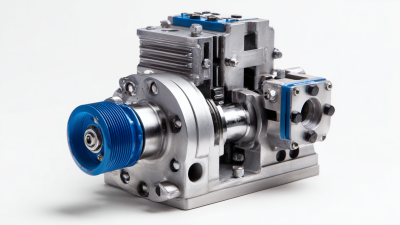

Eaton hydraulic motors play a vital role in various hydraulic systems, providing efficiency and power to a wide range of machinery and vehicles. At their core, these motors convert hydraulic energy into mechanical energy, enabling seamless operation across various applications. Understanding the essential components of Eaton hydraulic motors—such as the casing, rotor, and stator—is crucial for beginners looking to grasp their functionality. The configuration of these elements allows for the smooth transfer of hydraulic fluid, resulting in the rotational movement necessary for power generation.

The functionality of Eaton hydraulic motors can be likened to that of in-wheel motors in electric vehicles, where the principles of energy conversion are similarly applied. Both systems rely on the efficient management of energy, whether from hydraulic fluid or electric currents, to drive performance. In hydraulic motors, the pressurized fluid exerts force on the rotor, causing it to spin and ultimately power the machinery. By mastering these fundamentals, beginners can appreciate the intricate balance of design and operation essential for maximizing efficiency in hydraulic systems.

Mastering Hydraulic Motors - A Comprehensive Guide for Beginners

| Component | Functionality | Common Applications | Advantages | Considerations |

|---|---|---|---|---|

| Motor Housing | Encases the internal components | Construction equipment, agricultural machines | Durable, protects internal parts | Weight can affect mobility |

| Rotor | Converts hydraulic energy to mechanical energy | Forklifts, conveyors | High efficiency in energy transfer | Requires precise alignment for optimal performance |

| Gearbox | Adjusts torque and speed | Excavators, cranes | Versatile in different applications | Can add complexity to maintenance |

| Shaft | Transmits power to machinery | Dump trucks, loaders | Highly effective in power delivery | May require balancing for high speeds |

Selecting the Right Eaton Hydraulic Motor for Your Application Needs

When selecting the right Eaton hydraulic motor for your application needs, it is crucial to understand the specific operational requirements and characteristics of the project. Eaton offers a diverse range of hydraulic motors including gear, vane, and piston types, each designed for particular performance specifications. According to the International Fluid Power Society, approximately 70% of failures in hydraulic systems can be traced back to improper component selection. This reinforces the necessity of carefully assessing the hydraulic motor's torque, speed, and flow capacity to ensure compatibility with your equipment.

Moreover, a market analysis from ResearchAndMarkets indicates that the demand for hydraulic motors is expected to reach $6.51 billion by 2025, driven by increased use in agriculture, construction, and material handling industries. Understanding the specifics of your application—such as load requirements, environmental conditions, and available hydraulic supply—is essential for making informed decisions.

A well-chosen Eaton hydraulic motor not only enhances efficiency but also contributes to reducing operational costs by minimizing maintenance and downtime. Therefore, investing time in selecting the correct model is paramount for achieving optimal system performance.

Common Issues with Eaton Hydraulic Motors and How to Troubleshoot Them

When dealing with Eaton hydraulic motors, it's important to be aware of common issues that can arise, much like the valve lifter problems noted in recent automotive reports. Beginners might encounter challenges such as inadequate pressure, noise during operation, or decreased efficiency, all of which can stem from various underlying factors. Recognizing these symptoms early on can save both time and costly repairs.

Troubleshooting starts with a careful inspection of the hydraulic fluid. Contaminated or degraded fluid can lead to many performance issues, including overheating and lubrication failure. Checking for leaks in the system is also crucial, as even small leaks can significantly impact motor performance. Furthermore, understanding the specific model and its common failure points can assist in pinpointing the root cause, facilitating a more effective repair process. By following systematic troubleshooting steps, users can enhance the lifespan and functionality of their Eaton hydraulic motors.

Maintenance Best Practices for Longevity of Eaton Hydraulic Motors

When it comes to maintaining Eaton hydraulic motors, adopting a systematic maintenance mindset is crucial for ensuring their longevity and optimal performance. One of the key aspects of effective maintenance is following best practices for lubrication management. Implementing comprehensive lubrication strategies, as outlined in internationally accepted standards, can significantly enhance the operational lifespan of these motors.

The adoption of standards such as ICML 55.1 not only provides a framework for lubrication but also aligns with asset management principles. By focusing on lubrication best practices, operators can reduce wear and tear, minimize breakdowns, and ultimately improve the reliability of hydraulic systems. Regular monitoring, proper selection of lubricants, and adherence to prescribed intervals for lubrication are integral to maintaining the efficiency of Eaton hydraulic motors, ensuring that they operate smoothly and effectively throughout their service life.

Maintaining Eaton Hydraulic Motors: Best Practices for Longevity

Exploring Innovative Solutions: Enhancements in Eaton Hydraulic Motor Technology

Eaton has made significant strides in hydraulic motor technology, particularly with its recent innovations that blend hydraulic systems with electric components. This hybrid approach is exemplified in projects like the development of hydraulic hybrid systems for refuse trucks, showcasing how integrating these technologies can lead to substantial fuel savings and enhanced efficiency. This trend reflects a broader shift in the industry toward more sustainable and economical solutions, crucial for meeting modern environmental standards.

Another noteworthy development is Eaton's collaboration with defense contractors to support the US Army's Future Long-Range Assault Aircraft. By harnessing hydraulic technology, these advancements promise improved performance in military applications, enhancing operational capabilities while maintaining energy efficiency. As the hydraulic systems market continues to grow, the integration of advanced technologies like hydraulic hybrids will likely play a pivotal role in shaping future applications across various sectors, from transportation to defense.

Related Posts

-

Understanding Industry Production Standards for Best Eaton Hydraulic Motors

-

Top Strategies for Maximizing Efficiency with the Best Hydraulic Machine in Your Industry

-

Ultimate Hydraulic Repair Checklist for Optimal Performance

-

The Next Generation of Hydraulic Pump Motors Innovation and Impact

-

15 Reasons Why Best Hyd Pumps Are Essential for Your Business Success

-

Future Trends in Best Hydraulic Pump Market Analysis for 2025 Business Growth Insights